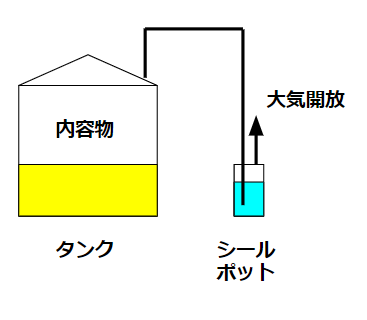

Seal pots are small but important devices used in pumps and mechanical seals. They help keep the seal system working smoothly by supplying clean fluid to the seal.

If you’re new to plant engineering or industrial equipment, the concept might seem confusing. Don’t worry — this article will explain what a seal pot is, how it works, and what it’s made of, using simple language and diagrams.

Let’s get started!

What Is a Seal Pot?

A seal pot is a small tank connected to a mechanical seal system.

Its main job is to hold and supply clean fluid (often called barrier or buffer fluid) to the mechanical seal.

This clean fluid helps:

- Cool the seal

- Lubricate the seal face

- Keep dirt or gas from entering the pump

Seal pots are often used in chemical plants and factories where the equipment runs continuously and cannot afford leaks.

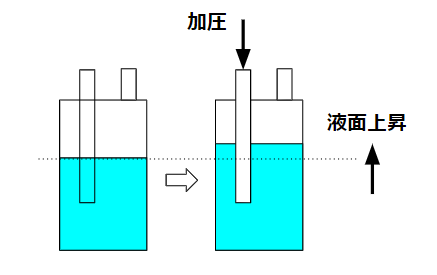

How Does a Seal Pot Work?

Here’s the basic flow:

- The clean fluid in the seal pot is pushed toward the seal by pressure or circulation.

- The fluid creates a protective layer around the seal face.

- After passing through the seal, the fluid may return to the seal pot or go elsewhere.

Many seal pots use natural circulation, where the fluid flows because of temperature or pressure difference — no pump needed.

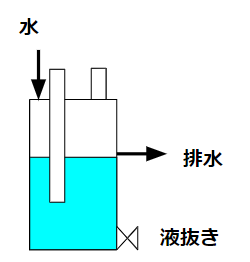

What Is Inside a Seal Pot?

A typical seal pot includes:

- Main Tank: Holds the fluid (usually 3–10 liters)

- Sight Glass or Level Gauge: Shows how much fluid is inside

- Thermometer: Monitors temperature

- Vent Valve: Removes air from the tank

- Drain Valve: Empties the tank for maintenance

- Cooling Coil (optional): Keeps the fluid from overheating

Here’s a simple diagram of a basic seal pot structure:

Types of Fluids Used

The fluid depends on the process. It can be:

- Clean water

- Oil

- Glycol mix

- Chemical-compatible liquids

The key is that the fluid should not react with the process or equipment and should remain clean.

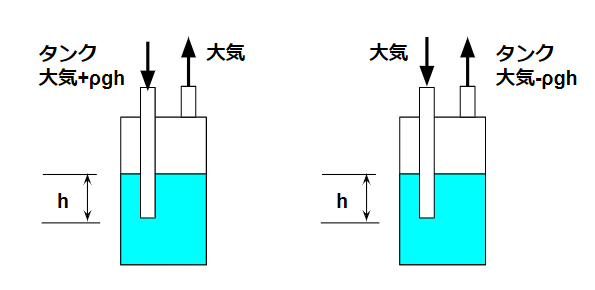

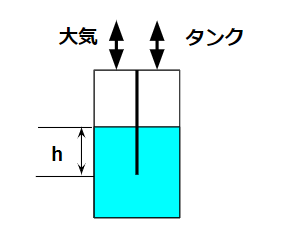

Seal Pot vs. Thermosyphon Pot

Some people confuse seal pots with thermosyphon pots. They are similar, but:

- Thermosyphon pots are often pressurized and sealed

- They are more common in API Plan 53 systems

- Seal pots may be vented (open to atmosphere)

Summary

Seal pots play a vital role in keeping mechanical seals healthy and leak-free.

For beginners in plant or pump maintenance, understanding their structure and function is a great first step.

Remember:

- They store and supply clean fluid

- Their structure is simple but effective

- Choosing the right fluid and checking levels regularly is key

Even though seal pots are small, they help protect big machines in your plant.

About the Author – NEONEEET

A user‑side chemical plant engineer with 20+ years of end‑to‑end experience across design → production → maintenance → corporate planning. Sharing practical, experience‑based knowledge from real batch‑plant operations. → View full profile

Comments