In chemical plants, refrigeration systems are critical for properly removing reaction heat and maintaining safe operation. If a chiller fails, the plant may shut down immediately. In some cases, the consequences can escalate to runaway reactions, fire, or even explosion.

This article explains the essential fundamentals of refrigeration systems that mechanical and electrical engineers should understand, along with practical considerations that matter in real operations.

While professional certification related to refrigeration machinery is important, practical understanding of system behavior is often far more critical in day-to-day plant engineering.

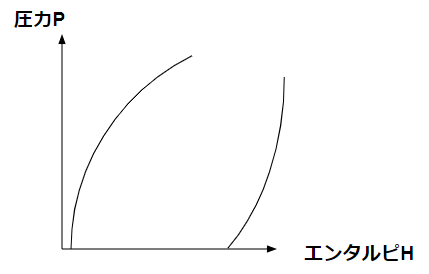

Understanding the p-h Diagram in Refrigeration: A Beginner’s Guide

Principle of Refrigeration

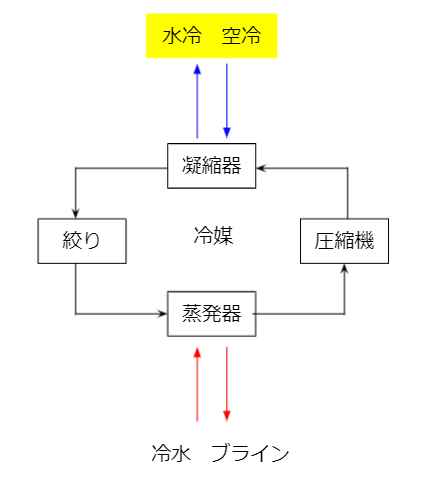

A refrigeration system operates on a closed thermodynamic cycle. The refrigerant circulates through four primary components:

- Evaporator

- Compressor

- Condenser

- Expansion device

The refrigerant flows in a continuous loop:

Evaporator → Compressor → Condenser → Expansion → Evaporator

Evaporator

Inside the evaporator:

- Process fluid is cooled

- Refrigerant absorbs heat and evaporates

It is called an evaporator because the refrigerant undergoes phase change there.

Compressor

The vaporized refrigerant is compressed to a high-pressure, high-temperature state.

Condenser

Inside the condenser:

- Refrigerant releases heat and condenses

- External cooling medium (air or water) absorbs the heat

Expansion Device

The high-pressure liquid refrigerant is throttled and expanded, reducing pressure and temperature before returning to the evaporator.

In screw-type chillers, a lubrication oil cycle also exists. Oil-related issues often become major maintenance concerns.

Why Refrigeration Systems Are Used

From a chemical plant perspective, refrigeration systems are required because:

- Low-temperature reactions are needed

- Cooling water consumption must be reduced

Without refrigeration systems, large volumes of cooling water would need to be continuously discharged. This increases environmental impact and may require seawater usage, which introduces corrosion risks.

Refrigeration systems allow reduced cooling water dependency and improved temperature control.

Brine (Secondary Coolant)

Brine refers to antifreeze solutions used as secondary cooling media. Originally it meant salt water, but today various fluids are used.

Chemical plants often require cooling below 0°C. Brine enables this safely.

Ethylene Glycol

The most common brine is ethylene glycol.

- Melting point: −12.6°C

- Boiling point: 111°C

It remains liquid below 0°C and is suitable for refrigeration systems.

However, at very low temperatures (e.g., −40°C concentration):

- Viscosity increases sharply

- Thermal conductivity decreases

Focusing only on temperature may compromise heat transfer performance.

Ethylene glycol is also classified as a hazardous material, requiring fire safety considerations.

Calcium Chloride / Sodium Chloride

Inorganic brines such as calcium chloride and sodium chloride are also used.

Their main drawback is corrosion:

- Salt presence

- High dissolved oxygen at low temperature

Both carbon steel and stainless steel may suffer corrosion. Application must be carefully selected.

Refrigerant

The refrigerant is the core of the system.

Temperature Requirements

A refrigerant must:

- Evaporate below brine temperature

- Condense above ambient temperature

Phase change at appropriate temperature ranges is essential for heat exchange.

Pressure Requirements

- Evaporating pressure should be above atmospheric pressure

- Condensing pressure must be within compressor capability

If evaporating pressure falls below atmospheric pressure, air ingress may occur, degrading system performance.

Ozone Depletion

Historically, chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) were widely used because of excellent thermodynamic stability.

However, chlorine-containing refrigerants contribute to ozone layer depletion. This led to global regulation and the shift toward non-CFC refrigerants.

Global Warming

Even after ozone-friendly refrigerants were introduced, global warming potential (GWP) became another regulatory concern.

Modern refrigerant development must balance:

- Ozone depletion potential (ODP)

- Global warming potential (GWP)

- Toxicity

- Flammability

No perfect refrigerant exists; trade-offs are unavoidable.

Refrigeration Oil

Refrigeration systems cannot operate without lubrication oil.

Functions include:

- Compressor sealing

- Wear prevention

Oil circulates in a separate loop:

- Oil injection into compressor

- Oil-refrigerant separation

- Oil cooling

- Oil recirculation

Oil separators and oil coolers are required. Oil management often causes more maintenance issues than refrigerant itself.

Metal wear particles may clog filters, leading to system shutdown.

Types of Refrigeration Systems

Open, Semi-Hermetic, Hermetic Compressors

- Open type: Easy maintenance

- Hermetic: Factory service required

- Semi-hermetic: Field disassembly possible

Screw vs Turbo Compressors

- Screw: Suitable for large capacity (common in chemical plants)

- Turbo: Typically smaller capacity

Absorption chillers also exist but are less common in chemical plants.

Air-Cooled vs Water-Cooled Condensers

Air-Cooled Advantages

- Multiple-unit control possible

- Reduced cooling water usage

- Lower environmental dependency

- Compact footprint

- Easier automation

- Redundancy reduces production stoppage risk

In batch plants, installing multiple air-cooled units allows capacity redundancy.

Water-Cooled Advantages

- Long operational track record

- Easier noise management

- Fewer rotating components

Air-cooled systems require fan maintenance and noise considerations, especially near residential areas.

Explosion-Proof Considerations

Refrigeration systems require compressors and electrical components. In hazardous areas:

- Explosion-proof design increases capital cost

- Distance from hazardous areas increases piping cost

Proper balance between equipment cost and piping cost is essential in project planning.

Multiple Unit Control (Capacity Staging)

Operating multiple chillers allows:

- Load flexibility

- Risk mitigation

- Energy efficiency

However:

- Larger footprint required

- Slightly higher capital cost

Ignoring redundancy often results in production loss risk.

Summary

Refrigeration systems are critical for safe chemical plant operation.

Understanding refrigerants, brine selection, oil systems, compressor types, cooling methods, explosion-proof requirements, and multiple-unit control directly supports plant design, operation, and maintenance.

Especially for risk mitigation and operational stability, redundancy and proper management are indispensable.

If you have questions related to plant design, maintenance, or operation, feel free to leave a comment.

Comments