Chemical plants consume enormous amounts of water—often far more than the products themselves.

At the foundation of this water usage lies industrial water.

At first glance, industrial water may seem like nothing more than water for cooling or cleaning. In reality, it supports the entire plant by branching into multiple utilities such as firefighting water, cooling water, potable water, process water, and steam.

Even among plant engineers, surprisingly few people have a clear, systematic understanding of where industrial water is ultimately used and how it is transformed across the plant.

This article organizes the uses of industrial water in chemical plants by application and explains the overall utility system in a way that beginners can easily understand.

In recent years, water recycling has also become an increasingly important topic—not only for plant engineers, but for surrounding communities as well.

5 Essential Utilities in Chemical Plants (for Beginners)

What Makes Instrument Air Special in Chemical Plants?

Steam Is More Dangerous Than You Think|Risks of Burns, Static Electricity, Corrosion, Blockage, and Equipment Damage

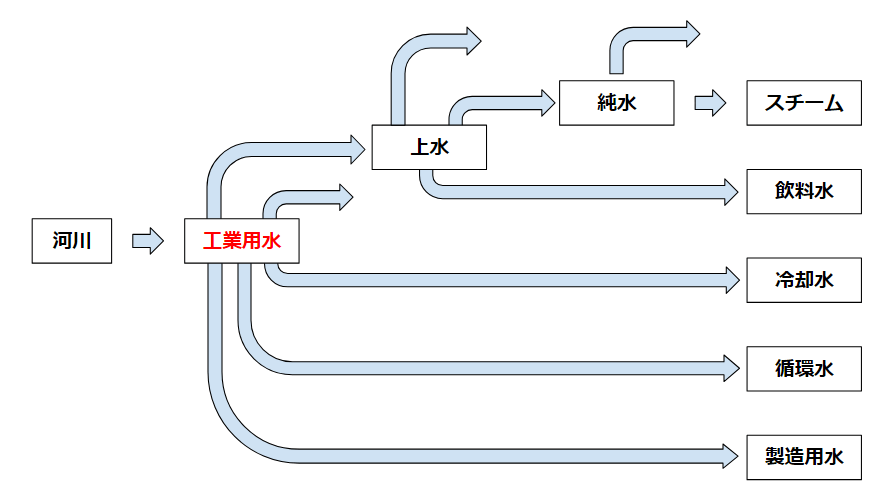

Industrial Water Derivatives

Industrial water drawn from rivers or other sources is reused and transformed into various utilities throughout the plant. While the full process flow is complex, this article focuses on the final applications.

Firefighting Water

The primary purpose of industrial water in a chemical plant is fire protection.

In the event of a fire, large volumes of water must be immediately available. Searching for water during an emergency is unacceptable. Municipal water supplies simply cannot provide sufficient flow rates for industrial firefighting.

For this reason, plants maintain dedicated water pools or reservoirs connected to pumps that can operate continuously and start instantly when needed.

Firefighting systems such as water spray or foam systems are designed so that pumps start automatically, as required by regulations.

Cooling Water

Industrial water is widely used as cooling water because:

- Liquids transfer heat more effectively than gases

- Water can flow through piping, providing large heat capacity

- Water is readily available in large quantities (especially in Japan)

- Water temperature is close to ambient conditions

As a result, cooling with gases or solids is rarely practical.

Depending on location, plants may use river water or seawater. Facilities with large cooling demands often rely on seawater, which is why many chemical plants are located near the coast.

Once-through cooling with industrial water consumes enormous volumes, so most plants use circulating cooling water systems with cooling towers.

Modern plants typically use circulating water for heat exchangers, although older plants may still use industrial water directly.

Seal water for centrifugal pumps is often supplied directly from industrial water. Chilled water (from chillers) and brine systems are also derived from industrial water.

Potable Water

Industrial water can also be treated and used as drinking water, though this requires dedicated purification processes.

In some plants, potable water is produced on-site from industrial water, while others rely on municipal water supplies.

Many plant workers prefer not to drink water treated within the facility—a sentiment that often surprises people outside the industry.

Process Water

Industrial water is also converted into process water used directly in manufacturing.

While the purity requirements are extremely strict in industries such as pharmaceuticals or semiconductors, even general chemical plants require a certain level of water quality.

Dedicated treatment systems are therefore necessary—but the original source is still industrial water.

Steam

Industrial water is also used to generate steam, which serves as a heating utility.

Raw industrial water is far too impure for boiler use. Producing boiler feedwater requires extensive treatment to achieve high purity, such as demineralized or pure water.

Hot water systems created by mixing steam and water are also ultimately derived from industrial water.

Conclusion

Industrial water is a fundamental utility in chemical plants.

- It branches into firefighting water, cooling water, potable water, process water, and steam

- Circulating cooling water systems are a key resource-saving strategy

- Water consumption and recycling will become increasingly important

Understanding how industrial water is used is directly linked to safety, energy efficiency, and environmental performance.

Before improving equipment or revising operating conditions, it is essential to first grasp the overall picture.

About the Author – NEONEEET

A user‑side chemical plant engineer with 20+ years of end‑to‑end experience across design → production → maintenance → corporate planning. Sharing practical, experience‑based knowledge from real batch‑plant operations. → View full profile

Comments