In chemical plant piping design, operability and safety are always major concerns. A layout that looks technically correct from a process or quality standpoint can still create serious operational risks if it is difficult or unsafe for people to access and operate.

Designers are often forced to look for compromises when good process design conflicts with real-world operation. This article uses ground-level piping layout as a concrete example to explain how to balance operability, safety, and process quality in practical plant design.

This article is part of the Plant Design (Buildings & Layout) series.

Ground-Level Layout for Long-Distance Piping

Long-distance piping—such as lines connecting different plant areas or linking a plant to external facilities—is common in chemical plants. Once inside the site boundary, these pipelines are usually unavoidable and highly visible.

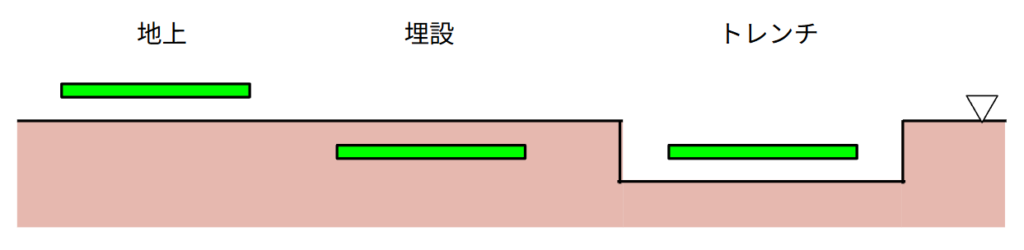

There are several typical layout options for long-distance piping:

- Ground-level (including pipe racks)

- Buried piping

- Trench piping

This article focuses on why ground-level layout is often the preferred option, while still acknowledging its drawbacks.

At first glance, ground-level piping seems obviously superior. Valves are accessible, leaks are easier to detect, and inspection is straightforward. However, ground-level layouts also introduce challenges:

- Higher risk of liquid exposure

- Obstruction of personnel movement

- Reduced space for temporary construction or maintenance equipment

Buried and trench layouts also have clear advantages and disadvantages. In general terms:

- Ground-level piping: Easy access and inspection, but higher exposure risk and reduced mobility

- Buried piping: Lower exposure risk and better accessibility for people and equipment, but poor inspectability and difficult drainage

- Trench piping: Partial visibility and reduced exposure risk, but poor access, fall hazards, and drainage challenges

Which option should be prioritized depends on the design philosophy of the plant.

For example, water lines are often buried under the assumption that liquid exposure is not a concern. Initially, this works well. Over time, however, corrosion problems become apparent—an issue frequently seen even in urban infrastructure. At that point, operators may decide to relocate buried piping to ground level to improve maintainability, accepting the significant retrofit cost as unavoidable for long-term operation.

Ground-Level Placement of Operated Components

For piping systems, components that require frequent operation or inspection should generally be placed at ground level. Two representative examples are discussed below.

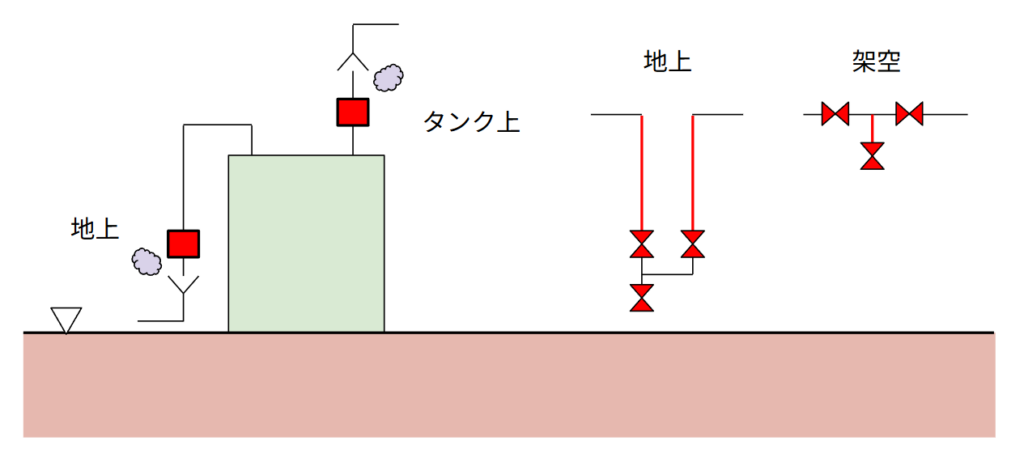

Flame Arresters

Consider a flame arrester installed on a flammable liquid storage tank.

By design, flame arresters are installed on gas lines, which typically places them at the top of the tank. Periodic inspection is required, meaning personnel must access elevated locations using ladders or stairs. This introduces fall risks and operational difficulty.

To mitigate these risks, designers sometimes relocate flame arresters to ground level.

Ground-level placement significantly reduces fall and trip hazards. However, it partially compromises the original functional intent of the flame arrester:

- Condensate is more likely to accumulate

- Personnel may be exposed to leaked gas

- Gas dispersion may be less effective than at elevation

Typical inspection-related risks include:

- Direct contact with flammable gas

- Musculoskeletal injury from handling heavy elements

- Contact with condensate

- Uncontrolled gas release into the surrounding area

At first glance, tank-top installation appears safer. In reality, the overall risk difference is often smaller than expected.

Gas dispersion from elevated locations helps, but the most effective risk reduction is preventing gas generation in the first place through proper process control. In modern plants with high automation and limited human presence, the likelihood of unintended personnel exposure near ground-level flame arresters is also relatively low.

If a structured risk assessment shows no significant difference, ground-level installation becomes a reasonable and defensible design choice.

Drain Valves

Drain valves should be positioned to minimize liquid hold-up. This is the safest configuration from a process standpoint.

When piping is installed on racks or at high elevation, drain valves are also located high above ground. Operating them requires scaffolding or tall ladders, significantly increasing the risk of falls.

Relocating drain valves to ground level improves operability and safety. The trade-off is increased liquid hold-up.

Designers must evaluate whether:

- The increased hold-up volume is acceptable

- The residence time affects product quality or impurity levels

- More frequent draining is required

If these impacts are judged acceptable, ground-level placement is justified.

In practice, the slight increase in piping length required for ground-level routing is rarely a deciding factor and is usually negligible compared to safety and operability benefits.

Conclusion

Ground-level piping layout should not be treated as an absolute rule or an automatic best practice.

Instead, designers should explicitly evaluate:

- Operability and ease of access

- Personnel safety

- Process quality and functional performance

Ground-level placement often improves safety and maintenance efficiency, but it can introduce new process-related risks. The correct solution is not about finding a single “right answer,” but about defining what level of compromise is acceptable for the plant.

Clear design intent, documented risk assessment, and alignment with plant philosophy are essential for making these decisions sustainable over the life of the facility.

About the Author – NEONEEET

A user‑side chemical plant engineer with 20+ years of end‑to‑end experience across design → production → maintenance → corporate planning. Sharing practical, experience‑based knowledge from real batch‑plant operations. → View full profile

Comments