Chemical plants handle a wide range of liquid raw materials.

A fundamental design decision is where to locate the raw material storage tanks.

Should tanks be centralized in one tank yard, or distributed near each individual plant unit?

This decision affects not only day-to-day operations, but also long-term maintenance cost, safety management, and future flexibility.

This article compares centralized and distributed tank layouts from the perspectives of operation, maintenance, and long-term risk.

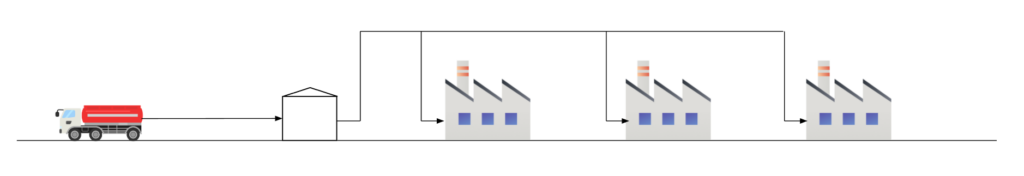

1. Centralized Tank Configuration

The simplest arrangement is to gather all raw material tanks in a single location — commonly referred to as a tank yard system.

Advantages

1. Easier inventory and safety management

Centralized storage simplifies procurement control and inventory management.

Hazardous materials are confined to one area, making leak monitoring and safety management more straightforward.

2. Dedicated receiving operations

A specialized tank yard team can standardize unloading and receiving procedures, improving operational consistency.

Disadvantages

1. Limited flexibility

Large outdoor tanks are difficult to relocate.

If production lines change or expand, modifying the layout becomes challenging.

2. Risk of misrouting materials

When supplying multiple plants through header piping, valve misoperation can cause delivery to the wrong destination.

This presents not only safety risks but also cost accounting issues.

3. Long-term piping replacement risk

Centralized layouts often require long-distance piping.

After several decades, full piping replacement may require substantial capital investment.

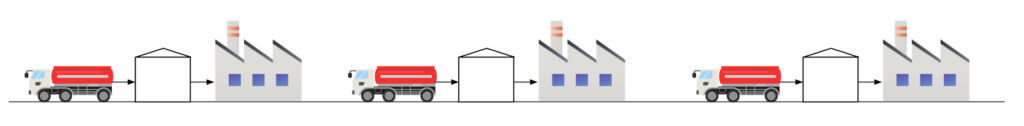

2. Distributed Tank Configuration (Per Plant Unit)

In this configuration, tanks are installed close to each individual production unit.

Advantages

1. Shorter piping distance

Reduced piping length lowers long-term maintenance and replacement costs.

Over a 30–40 year plant lifecycle, this difference can become significant.

2. Greater flexibility

If a production unit is repurposed or shut down, nearby tanks can potentially be reassigned more easily than large centralized tanks.

Disadvantages

1. Increased receiving workload

Each plant unit must manage its own receiving operations, increasing operational burden.

2. More complex inventory management

Purchase orders and stock control become more complicated due to multiple storage points.

3. Larger site footprint

Distributed tanks occupy more space across the overall plant site.

Key Design Considerations

There is no universally correct answer.

The appropriate decision depends on:

- Long-term piping renewal risk

- Likelihood of production changes

- Hazard level of stored materials

- Organizational management structure

The critical point is to evaluate not only initial capital cost, but also lifecycle maintenance and renewal costs over several decades.

Conclusion

The location of raw material tanks significantly influences:

- Operational efficiency

- Safety management

- Long-term piping renewal risk

- Future production flexibility

Centralized layouts simplify management but introduce long-distance piping risks.

Distributed layouts enhance flexibility but increase operational complexity.

Plant designers should evaluate both short-term efficiency and long-term lifecycle impact when making this decision.

About the Author – NEONEEET

A user‑side chemical plant engineer with 20+ years of end‑to‑end experience across design → production → maintenance → corporate planning. Sharing practical, experience‑based knowledge from real batch‑plant operations. → View full profile

Comments