In chemical plants and manufacturing facilities, tanks often have a portion of liquid that cannot be completely discharged from the bottom. This remaining liquid is commonly referred to as dead volume (or dead stock).

This phenomenon is especially unavoidable in outdoor tanks or tanks with side nozzles.

In this article, we explain why dead volume occurs and how it should be handled in practical operations. The content is particularly useful when introducing new liquids or planning cleaning work.

This article is part of the Tank Structure Series and the Pre-Maintenance Cleaning Series.

Essential Tank Terminology for Chemical Engineers|Master the Words Used in Real Plant Design

9 Common Tank Nozzle Design Patterns for Chemical Plants

Tank Nozzle Orientation: Practical Guidelines for Design and Operation

Designing Tank Manholes: Key Points for Safety and Maintenance Efficiency

Pressure Testing in Tanks and Piping: Understanding Leak, Hydrostatic, and Water-Filling Tests

Understanding Design Pressure in Chemical Plant Tanks: A Practical Guide

What Is Dead Volume in a Tank?

First, let’s clarify what “dead volume” means in tank design and operation.

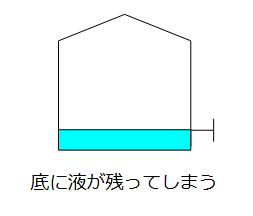

In outdoor tanks, the tank bottom is usually in full contact with a concrete foundation. Because of this, outlet nozzles are typically installed on the side, not at the very bottom.

Why side nozzles create dead volume

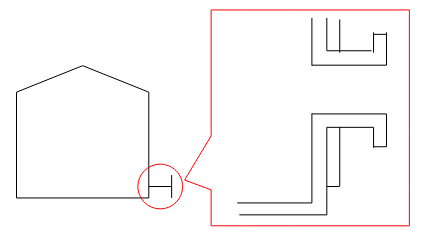

Installing a nozzle at exactly the same height as the tank bottom plate is extremely difficult.

Even if welding is attempted, any failure could lead to catastrophic leakage. For this reason, bottom plate welds are minimized as much as possible.

Additionally, a side nozzle locally reduces structural strength, so reinforcement plates are often required. To avoid excessive welding effects and ensure mechanical integrity, the nozzle must be installed slightly above the bottom plate.

As a result, when liquid is discharged from the tank, a layer of liquid equal to the nozzle height remains inside.

This remaining liquid is called the dead volume (or dead stock).

The Problem of Liquid Mixing

The real operational issue with dead volume appears when a tank is put back into service without being perfectly cleaned.

If the same liquid is used continuously, dead volume usually causes no trouble.

However, problems arise when liquids with different compositions are introduced, even if the solvent itself is the same.

For example, suppose liquids from Company A and Company B are interchangeable and can be mixed without concern.

Now imagine introducing a new liquid from Company C.

After laboratory evaluation shows no issues, a full-scale plant test is planned.

This is where dead volume becomes a concern.

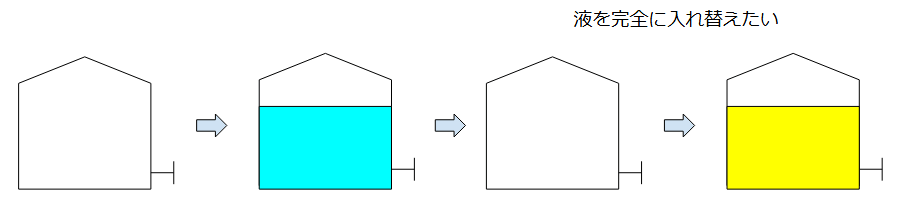

“We want to replace everything completely”

Ideally, operators assume that the tank contents can be fully replaced — cleaned to a completely fresh state — before receiving the new liquid.

In reality, because dead volume remains, complete replacement does not occur.

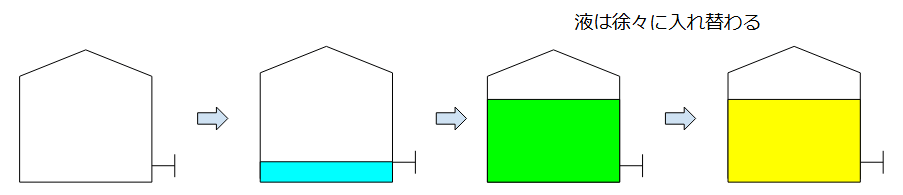

Instead, the new liquid gradually mixes with the residual liquid left at the bottom.

Whether this mixing causes a problem depends on the evaluation criteria.

If Company C’s liquid has looser requirements than A or B, slight contamination may be acceptable.

But if Company C’s formulation includes critical components, the plant test may unknowingly be conducted under more diluted conditions than intended.

This point is often overlooked during pre-evaluation.

Is Complete Drainage Impossible?

When we say “dead volume cannot be drained,” this is based on normal operating assumptions.

Draining dead volume takes time

If the internal piping is bent close enough to the tank bottom, it is theoretically possible to remove most of the remaining liquid.

However, doing so greatly increases the risk of air or nitrogen being entrained into the pump, which is unacceptable during normal operation.

In practice, after operations are finished and cleaning begins, pumps that tolerate gas entrainment — such as diaphragm pumps — may be used to remove as much dead volume as possible.

Then, heavier liquids like water (most organic solvents are lighter than water) are added to push residual solvent out from the bottom. Repeating this process several times can significantly reduce contamination.

Steam may also be introduced to raise the tank temperature, allowing solvents adhered to the walls and roof to flow down and be discharged.

Finally, after confirming that organic solvent no longer floats on water in the bottom section, personnel may enter the tank for manual cleaning.

At this stage, the tank can truly be considered clean.

Depending on solvent properties and manpower, this entire process can take over a month.

Why dead-volume pumping is rarely used in normal operation

Removing dead volume with a diaphragm pump before introducing new liquid would reduce mixing.

However, this increases waste volume and requires temporary piping and monitoring.

Because flow rates are small and permanent installation is impractical, this approach is generally avoided.

Conclusion

Dead volume is an unavoidable consequence of tank structure.

In tanks with side nozzles — especially outdoor tanks — complete drainage is inherently difficult.

Rather than attempting perfect removal, practical operations should focus on understanding and managing mixing risk during evaluations and operation planning.

With proper cleaning procedures and well-defined introduction steps for new liquids, safe and efficient operation can be achieved.

Comments