This article explains the functions and roles of pumps, aimed at new employees aspiring to become mechanical and electrical (M&E) engineers in chemical plants.

Although these are basic concepts, they are often overlooked because they seem simple.

Design engineers often focus on the next step, such as pump types (centrifugal, canned, magnetic), or pump performance curves. Maintenance engineers tend to focus on the pump structure and components such as mechanical seals.

However, mastering the basics is essential, and understanding them to the point of being able to explain in words is very important.

How to Select Pumps for Batch Chemical Plants: A Practical Guide for Engineers

Centrifugal Pump Basics: Understanding Structure, Components, and Key Functions

Canned vs. Magnetic‑Drive Pumps: How to Choose the Right Seal‑Less Pump

Why Mechanical Seals Leak in Pumps — and How to Fix It

Pump Functions

Let’s start with the basic functions of a pump.

Pumping Liquids

What is the purpose of a pump? Simply put:

To move liquids.

In manufacturing, we often move solid objects, such as products on a conveyor in a food factory or machinery using a crane. But pumps are used to move liquids, while gases are moved with fans, blowers, or air compressors.

Adding Pressure

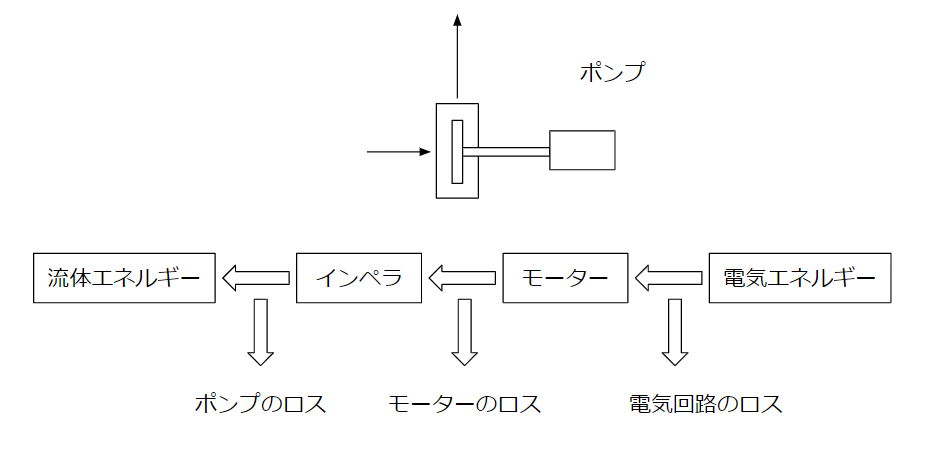

A pump adds energy to a liquid, creating high-pressure conditions.

The pump transfers rotational energy from the motor to the impeller. When liquid touches the spinning impeller, it is thrown outward by centrifugal force—like spinning an umbrella in the rain and causing water to fly outward.

By enclosing the impeller in a casing, the liquid’s escape routes are limited. The liquid then seeks to exit with high pressure, creating high-pressure, high-speed flow at the pump outlet.

Most pumps, over 99%, are centrifugal pumps using this principle. Other types may not use centrifugal force but still serve to increase pressure.

Transportation Through Piping

To move liquids, piping is essential. Piping controls the flow of liquids or gases.

Without piping, high-pressure liquid from a pump would simply disperse into the atmosphere. Piping defines a route, maintains flow, and generates pressure loss. This is a unique characteristic of liquids and gases.

Unlike solids, piping is not strictly necessary to control movement, but for liquids in chemical plants, piping ensures proper transport.

Pump Roles in Chemical Plants

Process

Pumps are widely used for chemical processes, which generally involve reactions in liquid phases. To transport these liquids to the correct locations, pumps are indispensable.

Many pipes are required, as different liquids must not mix and contaminate each other. Corrosive or flammable liquids may require pumps made of high-grade metals or seal-less pumps.

Utility

Pumps also handle utility water, which serves various purposes:

- Removing heat from reactions

- Condensing vapor back into liquids

- Cleaning equipment or process outputs

- Creating water seals to prevent leaks

- Cooling heat generated by shaft seals

Large volumes of water are often transported, making centrifugal pumps ideal. If these pumps fail, plant control becomes unstable, and shutdown procedures may be required.

Vacuum

Although pumps primarily increase liquid pressure, they can also reduce pressure for vacuum applications. Vacuum pumps operate opposite to standard liquid pumps.

References

- “Friendly Guide to Pumps” – Rinker

- “Mechanical Engineering Series: Pumps Basics – Selection, Operation, and Maintenance”

Conclusion

This article explained the functions and roles of pumps in chemical plants. Pumps are primarily used to pressurize liquids for chemical reactions and utility purposes, while piping ensures safe and efficient transport. Understanding these basics is crucial for design, maintenance, and plant operations.

Comments