This article shares my perspective on how to use TBM and CBM effectively.

In capital-intensive industries like chemical plants, equipment maintenance is critical.

Among the common maintenance strategies—TBM (Time-Based Maintenance), CBM (Condition-Based Maintenance), and BM (Breakdown Maintenance)—the choice between TBM and CBM often raises questions:

- “Which one should we choose?”

- “What exactly is the difference?”

Here, I’ll share my interpretation of TBM and CBM for chemical plants.

This article is part of the TBM series:

- TBM? CBM? BM? Are you using maintenance terms correctly?

- Considerations when changing TBM intervals

- TBM and CBM: Challenges even veteran engineers face

TBM, CBM, BM: Understanding Maintenance Terminology in Plants

Definition of TBM and CBM

TBM (Time-Based Maintenance) and CBM (Condition-Based Maintenance) are straightforward in concept:

- TBM: Replace parts at fixed intervals.

- CBM: Monitor conditions and replace parts as needed.

CBM implies continuous monitoring during operation, deciding on replacements based on actual equipment conditions.

However, in chemical plants where SDM or periodic maintenance occurs at fixed times, even CBM ultimately gets constrained by time, making TBM unavoidable in practice.

Field Interpretation of TBM and CBM

TBM:

- Maintenance required at fixed intervals.

- Often applied to core equipment like reactors, centrifuges, dryers, and chillers.

- Diagnostic data is used but serves mainly as reference.

CBM:

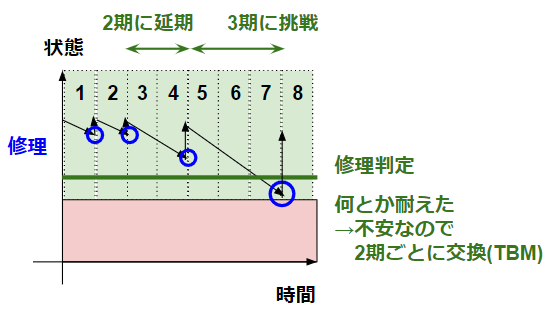

- Replacement timing is flexible, guided by observed condition trends.

- Applied mainly to pumps and heat exchangers.

- Prioritizes equipment with faster deterioration.

BM:

- No regular maintenance.

- Typically applied to storage tanks.

In practice:

- Core equipment → TBM

- Vulnerable equipment → CBM

- Low-impact equipment → BM

From a cost perspective, the goal is to stabilize annual expenses and predict long-term costs. CBM mainly helps plan repairs for the next period based on current monitoring.

Setting TBM Intervals

Determining TBM cycles is crucial for maintenance:

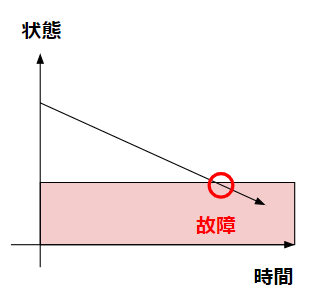

Degradation and Failure:

- Equipment degrades over time until failure occurs.

- For practical purposes, a clear judgment line is set.

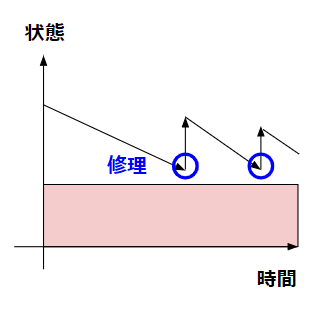

Repairs:

- Maintenance restores the equipment to a functional state, though not to its original condition.

- Equipment will degrade again after repair.

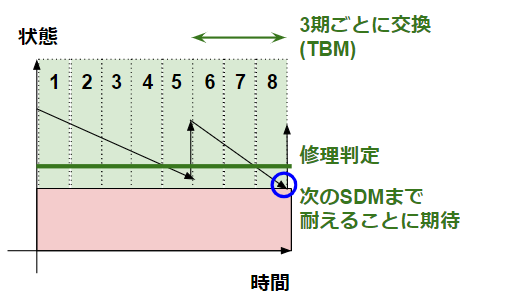

TBM Cycles (Based on Historical Data):

- Use cycles of similar equipment as a reference.

- Adjust based on repair judgment lines.

TBM Cycles (New Equipment):

- Start with shorter intervals, observe outcomes, then gradually extend cycles.

- Each cycle informs the next until a stable TBM schedule is established.

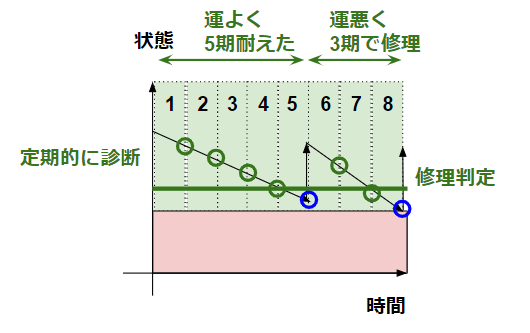

CBM Concept

CBM does not replace parts on a fixed schedule:

- Equipment condition is periodically monitored.

- Repairs are decided based on observed deterioration.

Challenges with CBM:

- Data collection is costly.

- Statistical analysis is required.

- Results are sometimes difficult to apply.

In batch plants, operating conditions fluctuate, so CBM may not function reliably without continuous, automated monitoring.

Improving equipment diagnostics via DX (digital transformation) aims to predict failures earlier and reduce risk.

Conclusion

When deciding between TBM and CBM for chemical plants:

- TBM is the foundation: Set cycles, allocate budget, and maintain critical equipment properly.

- CBM offers limited benefits in terms of repair cost; its main value is labor savings and optimizing resources.

Chemical plant engineers and operators are welcome to post questions or share concerns in the comments.

All comments will be carefully read and addressed.

Comments