Chemical plants handle a wide range of liquids and gases and must keep flow rates stable at all times. Among the various flow meters available, electromagnetic flow meters have a unique limitation: they only work with conductive liquids. This makes their proper placement surprisingly tricky.

This article explains where electromagnetic flow meters are suitable—and where they should be avoided—based on real chemical plant operations and piping layouts.

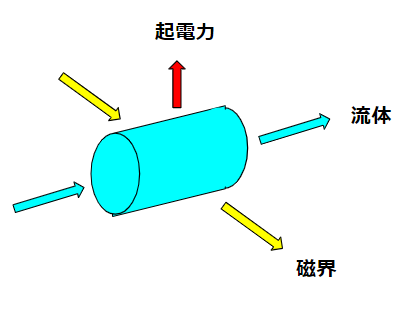

1. Reconfirming the Role of Electromagnetic Flow Meters

Chemical plants commonly use several types of flow meters: electromagnetic, vortex, Coriolis, variable area, and positive displacement.

Electromagnetic flow meters have a clear position:

suitable for conductive liquids and require minimal straight-run piping.

| Type | Typical Service | Straight Run | Pressure Loss | Cost |

|---|---|---|---|---|

| Electromagnetic | Water | Short | None | High |

| Vortex | Steam | Medium | Low | Medium |

| Coriolis | Oil | None | Medium | High |

| Variable Area | Oil/Gas | None | Low | Low |

| Positive Displacement | Calibration-free | Long | High |

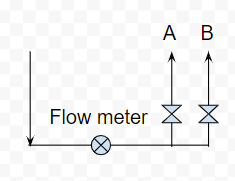

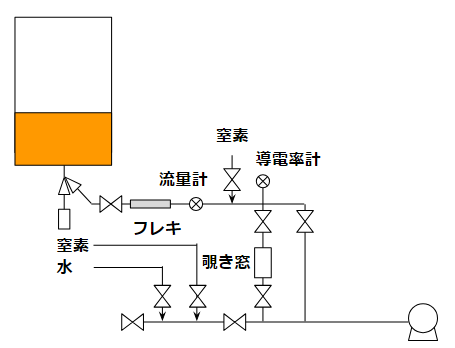

2. Water-Service Lines: The First Candidate

Because water is conductive, electromagnetic flow meters are widely used on water lines.

In batch-type plants, accurate water charging is critical. A combination of:

- flow meter

- header

- automated valves

allows precise control of the total water supplied to each reactor.

The control system closes the valve based on the accumulated flow value.

3. The Major Advantage: No Need for Long Straight Runs

Chemical plants—especially batch plants—are crowded with piping: switching lines, headers, and limited space.

Meters requiring long straight-run sections quickly become impractical.

Electromagnetic flow meters excel because they:

- require little straight piping

- reduce piping space occupancy

- fit easily in tight installations

4. Multiple Headers Are Often Required

Water is used by many reactors simultaneously. If only one header feeds 10–20 reactors:

- a single flow meter becomes over-occupied

- each reactor waits too long for its turn

Thus, plants commonly divide the system into 3–5 headers, each equipped with its own flow meter.

The minimal straight-run requirement of electromagnetic meters makes this multi-header layout easier.

5. Excellent for Acidic or Corrosive Liquids

Electromagnetic flow meters perform exceptionally well on acid lines due to:

- no moving internal parts

- availability of corrosion-resistant materials

- low failure likelihood even with harsh fluids

Other flow meter types often have shorter service life with corrosive liquids, making electromagnetic flow meters the first choice for acids in many plants.

6. Poor Suitability for Phase-Separation Lines

The biggest caution: do not use electromagnetic meters on phase-separating streams (oil + water).

Problems include:

- oil contamination causing unstable readings

- inaccurate values even on the “water side”

- significant measurement error with small oil intrusion

Electromagnetic flow meters can only provide “rough indication” at best on such lines.

Summary

Electromagnetic flow meters are powerful when used in appropriate locations—but their limitations are just as clear.

- Ideal for water and acid lines

- Very advantageous in tight spaces (short straight run)

- Work well with multi-header systems

- Not suitable for phase-separation or oil-contaminated lines

Understanding process conditions and placing electromagnetic flow meters correctly contributes directly to stable and safe plant operation.

Comments