In plant maintenance, reliability and maintainability are crucial. Key indicators like MTBF (Mean Time Between Failures), MTTR (Mean Time To Repair), and availability help quantify how reliable equipment is and how quickly it can be restored.

If you’re new to maintenance, these terms can be confusing. This article explains their meanings, formulas, and practical applications so you can use them effectively in plant operations and maintenance planning.

1. What Are Reliability and Maintainability?

Reliability and maintainability indicate how consistently equipment operates and how quickly it can be repaired.

In chemical plants, downtime can be costly. Maintenance staff must not only fix problems but also anticipate them—like preventing equipment failures before they occur. Think of it as a health checkup for machines: monitoring, inspecting, and repairing proactively.

2. Reliability

Reliability is a measure of how unlikely equipment is to fail.

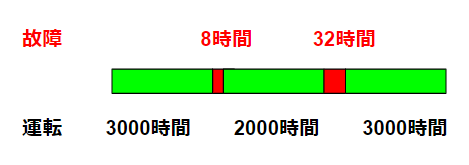

MTBF – Mean Time Between Failures

MTBF is the average time a piece of equipment operates before a failure occurs.

Formula: MTBF=Operating TimeNumber of Failures\text{MTBF} = \frac{\text{Operating Time}}{\text{Number of Failures}}MTBF=Number of FailuresOperating Time

Example:

If equipment runs 8,000 hours in a year and fails twice: MTBF=8000/2=4000 hours per failure\text{MTBF} = 8000 / 2 = 4000 \text{ hours per failure}MTBF=8000/2=4000 hours per failure

This predicts the expected operating time between failures and helps plan preventive maintenance.

Failure Rate

The failure rate is the reciprocal of MTBF: Failure Rate=Number of FailuresOperating Time\text{Failure Rate} = \frac{\text{Number of Failures}}{\text{Operating Time}}Failure Rate=Operating TimeNumber of Failures

In the above example: 2/8000=0.00025 failures per hour2 / 8000 = 0.00025 \text{ failures per hour}2/8000=0.00025 failures per hour

3. Maintainability

Maintainability measures how quickly equipment can be repaired.

MTTR – Mean Time To Repair

MTTR is the average time required to repair a failed system: MTTR=Total DowntimeNumber of Failures\text{MTTR} = \frac{\text{Total Downtime}}{\text{Number of Failures}}MTTR=Number of FailuresTotal Downtime

Example:

Two failures taking 8 and 32 hours: MTTR=(8+32)/2=20 hours per repair\text{MTTR} = (8 + 32)/2 = 20 \text{ hours per repair}MTTR=(8+32)/2=20 hours per repair

Failure Intensity Rate

Failure Intensity Rate=Total DowntimeOperating Time\text{Failure Intensity Rate} = \frac{\text{Total Downtime}}{\text{Operating Time}} Failure Intensity Rate=Operating TimeTotal Downtime (8+32)/8000=0.005(8 + 32) / 8000 = 0.005(8+32)/8000=0.005

This reflects lost production time and helps prioritize maintenance efforts.

4. Using Reliability and Maintainability Data

Maintenance is not just fixing broken equipment. It involves data-driven planning to improve equipment lifespan, reduce downtime, and optimize maintenance costs.

Collecting MTBF, MTTR, and availability data allows plant engineers to make informed decisions, justify maintenance budgets, and communicate effectively with management.

5. Further Learning Resources

For more advanced understanding of plant reliability and maintenance:

- Aging of Chemical Plants: Risk-Based Equipment Maintenance and Evaluation [CCPS / AIChE]

These resources discuss lifecycle management, long-term planning, and risk-based maintenance strategies.

6. Related Articles

- Plant Lifecycle Management

- Equipment Life Extension

- Maintenance Planning Tips

- Equipment Availability Optimization

Conclusion

MTBF, MTTR, failure rate, and availability are essential metrics for evaluating equipment reliability and maintainability.

Understanding these indicators allows you to:

- Identify improvement opportunities

- Plan preventive maintenance

- Optimize maintenance costs

- Reduce downtime

Even as a beginner, keeping these metrics in mind helps improve decision-making and ensures safer, more reliable plant operation.

About the Author – NEONEEET

A user‑side chemical plant engineer with 20+ years of end‑to‑end experience across design → production → maintenance → corporate planning. Sharing practical, experience‑based knowledge from real batch‑plant operations. → View full profile

Comments