Concentrated sulfuric acid is one of the most widely used—and most dangerous—chemicals in industrial plants.

Its strong corrosive nature means that even small design mistakes can lead to severe equipment damage or safety risks.

In this article, we’ll explain the five most important design points when dealing with concentrated sulfuric acid.

From tank materials to piping connections and pump selection, each section is based on real-world engineering experience.

This guide is written for beginner and junior engineers, helping you design systems that are both safe and durable.

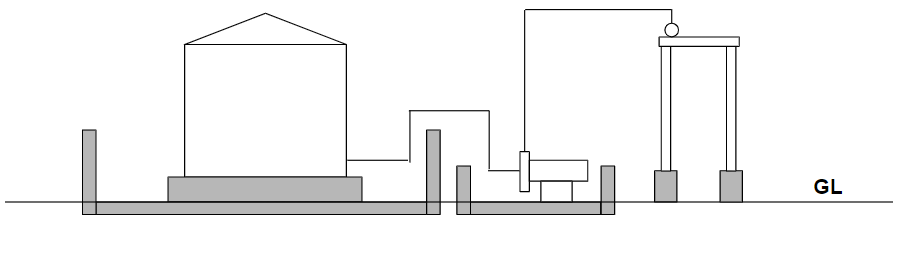

1. Tank Design

For sulfuric acid storage, metal tanks are usually the best choice.

For around 10 m³ capacity, glass-lined tanks can be used, but stainless steel (SUS304) or carbon steel (SS400) is more common and cost-effective.

- SS400 works with concentrated sulfuric acid, but becomes risky if the acid is diluted.

- SUS304 handles both concentrated and moderately diluted sulfuric acid but may corrode under other conditions.

When designing, minimize liquid accumulation areas.

Any trapped moisture can form diluted sulfuric acid, which quickly accelerates corrosion—especially at weld seams and roof joints.

2. Gas Vent Line

The vent line should be designed to prevent rainwater entry.

Instead of an open vertical vent, use a 180° elbow facing downward.

Over time, moisture and air entering through the vent can cause acid dilution and corrosion.

In some cases, dry air or nitrogen purging is used to seal the vent line, though this depends on site policy.

3. Feed Pipe (Dip Tube)

Avoid splashing sulfuric acid from above the liquid surface—it increases mist and moisture contact.

Instead, install a dip pipe to feed acid below the liquid surface near the bottom plate.

To protect the bottom from erosion, add a wear plate.

Be cautious with flow velocity:

For carbon steel (SS400), too high a velocity removes the protective oxide film that gives it corrosion resistance.

This is one reason why SUS304 is often preferred for sulfuric acid systems.

4. Pump Selection

For safety, sealless pumps such as canned or magnetic-drive types are recommended.

Avoid pumps using carbon bearings—they can react dangerously with sulfuric acid.

Also, calculate pressure loss carefully.

Sulfuric acid has a density of 1840 kg/m³ and a viscosity of 26 cP (at 20 °C)—far higher than water.

If you size your pipes based on water, flow resistance will be much greater than expected.

As a rule of thumb, use one pipe size larger than you would for water service.

5. Piping Design

Use SUS304 for piping material.

Carbon steel (SGP or STPG) is not recommended, even with thicker walls.

Connections should be flanged (JIS 10K class) rather than threaded, which can easily leak under acid exposure.

For gaskets, joint sheet or PTFE-based materials are both good options.

Bolts and nuts can remain SS400, as they are outside the wetted area.

Conclusion(まとめ)

Designing systems for concentrated sulfuric acid requires careful attention to corrosion behavior, material selection, and temperature management.

It’s not just about piping—it affects tanks, pumps, valves, and other components throughout the system.

For young engineers, this is one of the most challenging yet rewarding areas of plant design.

Work closely with experienced colleagues, learn from the field, and always verify how corrosion and dilution risks apply to your actual system.

Comments