In chemical plants and industrial facilities, cooling towers play a key role in efficiently removing large amounts of heat.

Although they might look like simple rooftop installations, cooling towers are sophisticated systems that use the principle of water evaporation to cool process water.

This article explains, in plain terms, how cooling towers work — including their basic principles, internal structure, and practical water management techniques used in industrial settings.

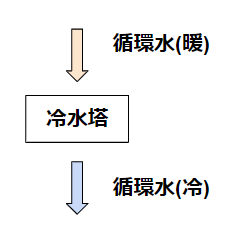

1. The Role of a Cooling Tower

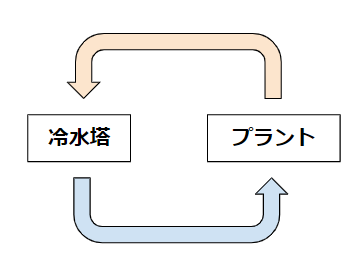

A cooling tower (also called a “cooling water tower”) is designed to cool down circulating water.

In a typical chemical plant, warm water absorbs process heat and is sent to the cooling tower, where it’s cooled by air before being recirculated back into the system.

This process is continuous, forming what’s called a cooling water circulation loop.

To avoid confusion, it’s good to distinguish between chilled water (used in chillers) and cooling water (used in towers).

2. Principle of Operation

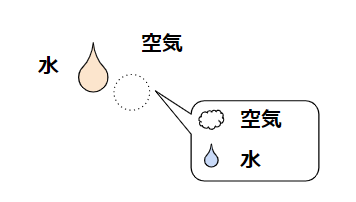

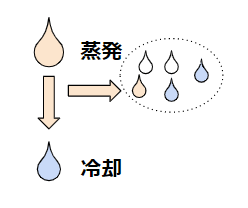

The cooling tower works based on the principle of evaporation.

When warm water comes into contact with air, a small portion of it evaporates.

This evaporation requires heat — known as the latent heat of vaporization — which is taken from the remaining water, lowering its temperature.

This is the same principle behind the cooling effect when water evaporates from your skin or after sprinkling water on a hot pavement in summer.

3. Structure of a Cooling Tower

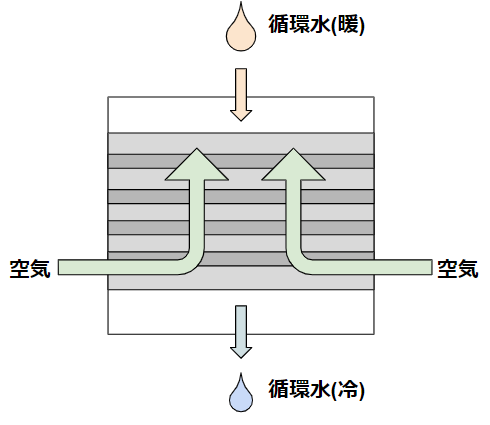

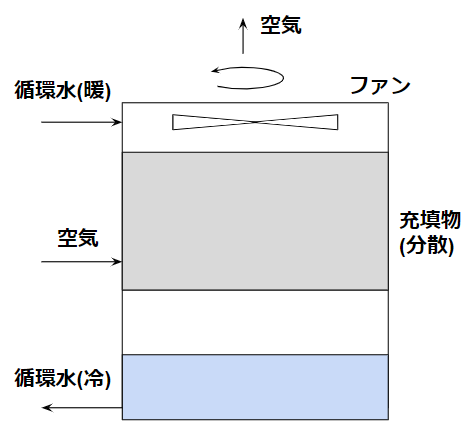

Cooling towers are designed to maximize contact between air and water, promoting evaporation.

They contain fill media (structured plastic or metal sheets) that spread the water into thin films or droplets, increasing the surface area for heat exchange.

Air flows through the tower — usually from the bottom upward — while water flows downward by gravity.

Fans at the top of the tower enhance air movement, helping maintain efficient cooling even in hot weather.

4. Key Components

Circulating Water Inlet

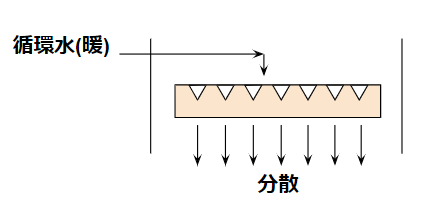

The inlet distributes warm water evenly across the tower, often using nozzles or slotted trays for uniform flow.

Fan

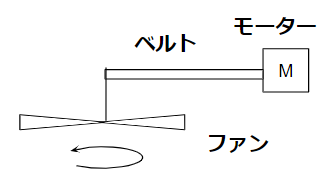

Fans located at the top (in induced-draft towers) or bottom (in forced-draft towers) promote upward airflow, ensuring efficient heat removal.

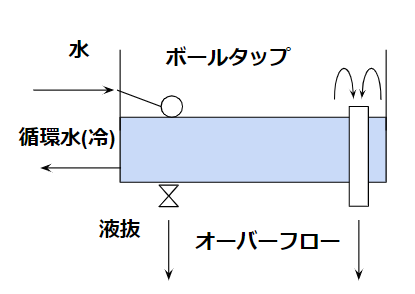

Circulating Water Basin

At the bottom, cooled water collects in a basin before being pumped back to the process system.

Proper design ensures enough volume for startup operations and stable water supply.

5. Optional Systems and Maintenance Points

Blowdown System

Because only pure water evaporates, impurities (salts, minerals) accumulate over time.

Blowdown periodically removes a portion of water to prevent scaling and corrosion.

Water Treatment

Chemical dosing systems add corrosion inhibitors and biocides to maintain water quality and equipment life.

Drift and White Smoke Prevention

In cold weather, visible “white smoke” (actually water vapor) can be mistaken for pollution.

To avoid this, temperature control or mixing warm and cool air streams is often implemented, especially in urban areas.

Conclusion

Cooling towers are essential for thermal management in chemical plants and factories.

They use simple physical principles — evaporation and air circulation — to remove process heat efficiently.

Understanding their design and water management helps engineers improve reliability, energy efficiency, and environmental performance across an entire facility.

About the Author – NEONEEET

A user‑side chemical plant engineer with 20+ years of end‑to‑end experience across design → production → maintenance → corporate planning. Sharing practical, experience‑based knowledge from real batch‑plant operations. → View full profile

Comments