Installing tanks in chemical plants requires careful attention to the bolts used to secure them. While bolts may seem minor, they play a critical role in the long-term stability and safety of the equipment. This article explains the three main types of installation bolts and provides guidance for selecting the most suitable method.

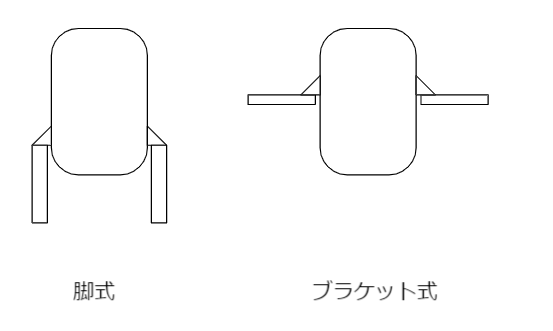

Tank Support Methods: Legs vs. Brackets

Chemical plant tanks are typically installed using either leg-supported or bracket-supported systems. While leg-supported tanks have some advantages, bracket-supported tanks are more commonly used due to their flexibility and efficient use of space.

Leg-Supported Tanks

- Advantages:

- Can reduce the size of structural beams and columns by transferring load directly to the foundation.

- Disadvantages:

- Requires independent concrete foundations.

- Limited applicability in plants with existing platforms or structures.

Leg Attachment Options

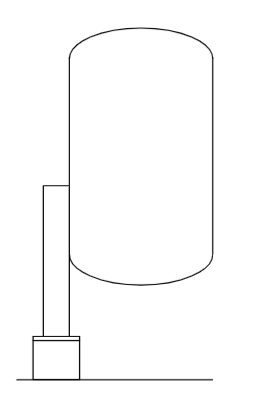

- From the Shell Plate:

- Most common method.

- Legs are welded to shell plates, sometimes using extra plates to avoid interference with shell welds.

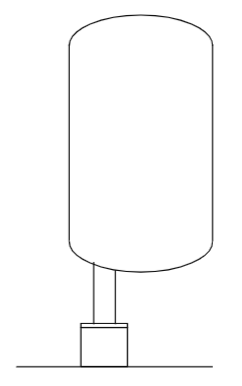

- From the Head Plate:

- Less common.

- Legs are welded to tank heads, introducing bending stress rather than tensile stress.

Comparison:

- Shell-attached legs provide higher strength due to tensile forces along the shell.

- Head-attached legs allow tighter leg spacing, useful in compact plants.

- Shell attachment offers better overturn stability.

Bracket-Supported Tanks

- Advantages:

- Eliminates the need for legs, maximizing floor space.

- Supports load closer to the tank’s center of gravity for improved stability.

- Reduces additional hardware like templates and support plates.

- Drawbacks:

- May require slightly larger structural beams, but usually not critical.

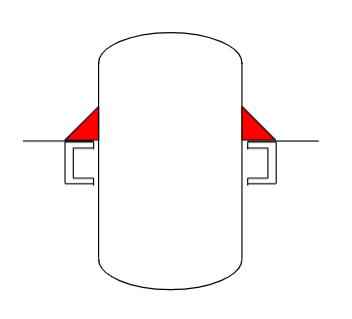

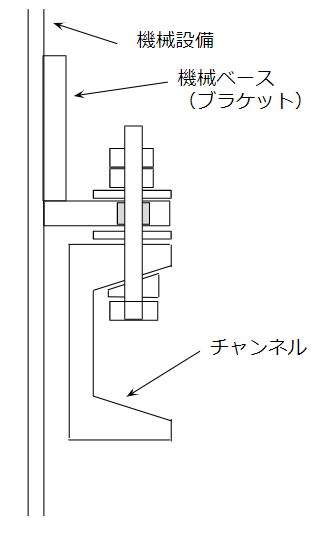

Installation Illustration:

- Tank brackets are bolted to beams or C-channels.

- Cross beams (small beams) connect brackets to main beams using gusset plates and bolts.

- Intermediate beams may be added for larger tanks to improve stability.

Installation Bolt Systems

- Bolt Sizes: Typically standardized by hole size (e.g., M12 for 15mm holes).

- Inclined Washers: Used to adjust for uneven surfaces on C-channels.

- Double Nuts: Prevent bolt loosening due to vibration.

- Washers: Distribute bolt load evenly to prevent local deformation.

- Shims (Liners): Fine-tune height and alignment during installation.

Anchor Bolt Types

- Embedded Bolts: High-strength but require precise placement.

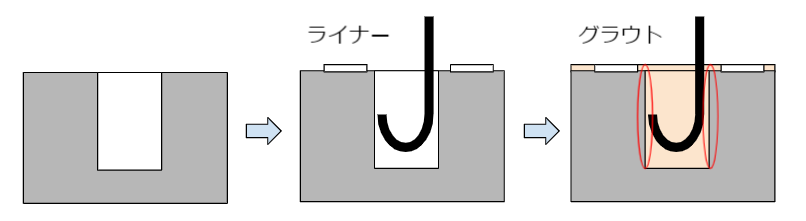

- Boxed Embed: Allows adjustments during installation; slightly lower strength.

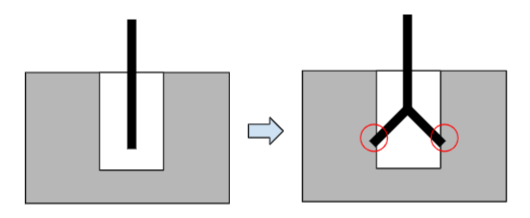

- Hole-In Anchors: Simplest, cost-effective; limited pull-out strength.

- Chemical Anchors: High-strength; compatibility with plant chemicals must be checked.

Maintenance Tips:

- Use caps to prevent corrosion.

- Stainless steel liners protect bolts in boxed installations.

- Welding can be a last-resort repair if bolts corrode.

Intermediate Legs & Templates

- Intermediate Legs: Facilitate transport and installation adjustments for large equipment.

- Templates: Ensure precise alignment of bolts and equipment during construction, avoiding costly on-site modifications.

Conclusion:

Understanding the differences between leg and bracket support, as well as the types of anchor bolts and installation techniques, is crucial for safe and efficient tank installation in chemical plants. Proper planning avoids construction errors, reduces maintenance issues, and ensures long-term equipment stability.

Comments