Preventing leakage of liquids and gases is one of the most critical challenges in chemical plants.

Rotating equipment such as pumps, agitators, and mixers always carry the risk of fluid leakage through the shaft.

To control this risk, various seal systems are used.

Understanding how seals work—and how to select the right type—is essential for safe operation, stable quality, and long equipment life.

This article explains the basic structure, classification, and selection philosophy of seals, in a way that is easy to understand for beginners in chemical and mechanical engineering.

Why Mechanical Seals Leak in Pumps — and How to Fix It

What Is a Gland Packing (Gland Seal)? A Clear Guide to Its Purpose, Mechanism, and Use Cases

Top 3 Mechanical Seal Flushing Plans Explained (API 682 Standards)

Essential Guide to Mechanical Seal Support Systems in Chemical Plants

When in Doubt, Choose a Double Mechanical Seal: Practical Reasons for Chemical Plants

What Is a Labyrinth Seal in Chemical Plants?

Seals Control Chemical Machinery

This article is part of a seal fundamentals series.

In chemical plants, seals are not just components—they define whether equipment can operate safely and continuously.

A poor understanding of sealing often leads to leakage, frequent maintenance, or even serious incidents.

Classification of Sealing Devices

In mechanical engineering, sealing devices are broadly classified into two categories:

- Static seals

- Dynamic seals

Understanding this distinction is the foundation of seal selection.

Gaskets: Static Seals

Gaskets are static seals, used where no relative movement occurs.

A typical example is a pipe flange gasket.

In practice, operators sometimes refer to flange gaskets as “packing,” but strictly speaking, this is incorrect.

From an engineering perspective, gaskets belong to static sealing, while packings and shaft seals belong to dynamic sealing.

Some O-rings are also used as static seals, depending on their application.

Packings and Dynamic Seals

Packings are dynamic seals, used where relative motion exists—typically at rotating or reciprocating shafts.

Common dynamic seals include:

- Gland packing

- V-packings

- Oil seals

- O-rings

- Mechanical seals

- Labyrinth seals

Dynamic seals can be further classified into:

- Contact seals

- Non-contact seals

Mechanical seals are often categorized as contact seals, but strictly speaking, their sealing faces are separated by a thin fluid film, making them closer to non-contact sealing.

Rubber-Based Seals and Their Principle

Oil seals, V-packings, and O-rings typically use rubber or elastomer materials.

The key reason rubber is effective as a sealing material is its ability to deform under pressure.

This deformation allows the seal to conform to surfaces and block leakage.

Oil Seals

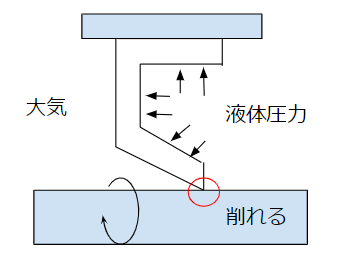

Oil seals are designed to deform under fluid pressure.

When pressure is applied, the seal lip expands and maintains contact with the rotating shaft.

Over time, the lip gradually wears, but as long as sufficient lip length remains, sealing performance is maintained.

Seal life is strongly influenced by:

- Shaft speed

- Pressure

- Fluid properties

- Seal geometry

Despite the name, oil seals are used not only for oil but also for various liquids and gases.

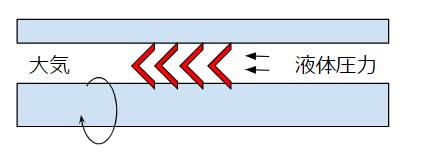

V-Packings

V-packings use the same pressure-assisted sealing principle as oil seals.

They are usually installed in multiple stages.

In practice, only one of the stacked packings actively seals at any given time, while others act as backups as wear progresses.

This staged wear concept is similar to gland packing and stacked oil seals.

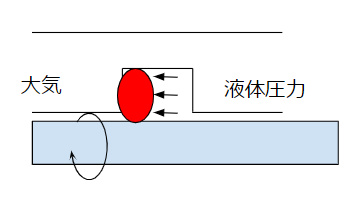

O-Rings

O-rings also rely on elastic deformation.

When pressure is applied, the O-ring is compressed against the groove walls to form a seal.

If pressure is excessive, the O-ring may extrude from the groove and fail.

O-rings are used in both:

- Static applications

- Dynamic applications

Design requirements differ significantly between the two.

Comparison: O-Rings vs V-Packings

| Item | O-Ring | V-Packing |

|---|---|---|

| Installation direction | No | Yes |

| Required space | Small | Large |

| Surface finish | High precision | Lower precision acceptable |

| Installation difficulty | Easy | Difficult |

| Adjustment | Not required | Required |

| Quantity | One | Multiple |

| Service life | Shorter | Longer |

V-packings are selected when longer life is required and additional space is acceptable.

In most batch-type chemical plants, O-rings are sufficient.

Seal Materials

Seal material selection is critical in chemical plants.

Typical guidelines:

- Process fluid contact: FKM, PTFE

- Non-process areas: NBR, BR, CR

FKM is often assumed to be universally suitable, but many batch processes involve chemicals that FKM cannot tolerate.

In such cases, FFKM or PTFE-coated seals may be required, though they are significantly more expensive.

Non-Rubber Sealing Systems

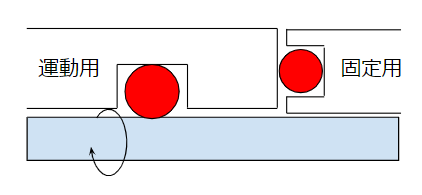

Mechanical Seals

Mechanical seals do not use rubber at the primary sealing faces.

The sealing interface consists of a rotating and stationary ring separated by a thin fluid film.

Rubber components are used only as secondary seals between the seal assembly and equipment.

Blowers and Fans

Some blowers and fans operate without shaft seals.

When leakage is acceptable or minimal, labyrinth seals may be used to restrict flow rather than completely block it.

Labyrinth seals reduce leakage by increasing flow resistance—a simple but effective concept.

Hydraulic Piping

Hydraulic systems often operate above 10 MPa.

Rubber gaskets may fail under such conditions.

In some cases, no gasket is used at all.

Instead, sealing is achieved through extremely high machining accuracy of flange surfaces—similar to the sealing principle of mechanical seal faces.

Conclusion

- Seals are among the most critical components for preventing fluid leakage.

- They are broadly classified into static and dynamic seals.

- Chemical plants require careful consideration of fluid properties, pressure, and operating conditions.

- Proper seal selection and maintenance directly reduce leakage incidents and extend equipment life.

Understanding seal fundamentals is essential for anyone involved in design, maintenance, or operation of chemical plant equipment.

About the Author – NEONEEET

A user‑side chemical plant engineer with 20+ years of end‑to‑end experience across design → production → maintenance → corporate planning. Sharing practical, experience‑based knowledge from real batch‑plant operations. → View full profile

Comments