In industrial equipment, certain parts are exposed to continuous stress, which can cause wear and eventual failure. Understanding when and how to replace these stressed parts is crucial to maintain safe and efficient operation.

Introducing articles from plantengineering.com.

Consider equipment maintenance, or restoration of functionality.

This is very important for the long-term operation of the plant, and can be considered as a management issue.

parts are replaced

When we use the broad term “equipment maintenance”, we can think of many things.

The principle is to replace parts.

When thinking about restoring functionality, there is the idea of repairing parts, but it is much safer to replace them.

Important maintenance issue will be how to optimize parts replacement.

Parts that are subjected to force deteriorate

When thinking about replacing parts, the most important part is the part where force is applied.

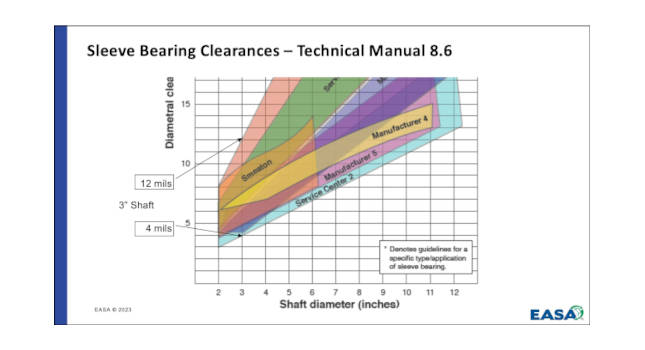

In the case of a pump, it is a bearing

This is the part that directly indicates the rotational force of the shaft, and force is constantly applied.

Naturally, not only the bearings but also the shaft receive force.

The wear ring inside the impeller is also the part that is most exposed to the pressure of the water in the pump.

Minimize the size of replacement parts

When replacing parts, you must consider minimizing costs.

For example, shafts are subject to wear and tear due to force, but it would be costly to replace the entire shaft.

Therefore, there is a general idea of minimizing the need to replace parts called sleeves.

The sleeve will wear out, but the shaft will not, so only a limited number of parts, the sleeve, need to be replaced.

The same goes for the wear ring inside the pump casing.

Conclusion

Replacing parts subject to stress is vital for reliability and safety in industrial equipment. Proactive maintenance protects your investment and ensures smooth operation.