Gaskets play a critical role in sealing piping systems and process equipment.

Their performance depends heavily on both material and construction, which directly affect leak tightness, durability, and applicability.

Among corrosion-resistant materials, PTFE (polytetrafluoroethylene) gaskets are widely used in chemical plants.

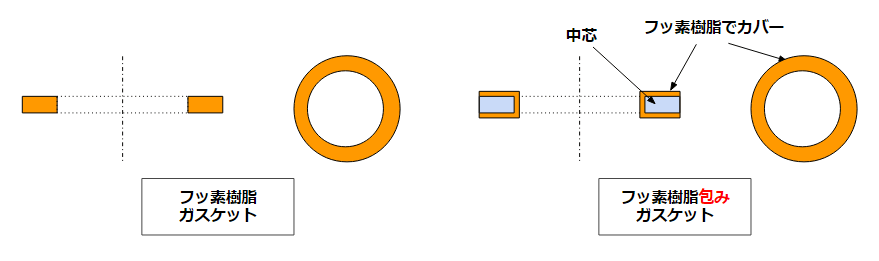

In practice, PTFE gaskets are generally classified into two types:

- PTFE solid gaskets (full PTFE)

- PTFE envelope gaskets (PTFE-jacketed gaskets)

Although both use PTFE as the sealing surface, their mechanical behavior and recommended applications differ significantly.

This article explains the key differences, advantages, and limitations of PTFE solid and PTFE envelope gaskets, focusing on batch chemical plant applications and real-world engineering considerations.

What Is a Spiral Wound Gasket? Structure, Features, and Practical Applications Explained

Principles and Selection of Gaskets: Key Sealing Technologies to Prevent Leakage

Gasket Factor (m) vs. Minimum Seating Stress (y):Key Differences, Typical Values, and Selection Tips

Overview of PTFE Gasket Types

PTFE gaskets used in chemical plants can be broadly divided into two categories:

- PTFE Solid Gasket

A gasket made entirely of PTFE. - PTFE Envelope (Jacketed) Gasket

A gasket where a soft core material (typically a non-asbestos compressed sheet) is covered with PTFE on the sealing surfaces.

The core material varies by manufacturer, but the concept is the same:

chemical resistance from PTFE + compressibility from the core.

PTFE Solid Gaskets (Full PTFE)

General Characteristics

PTFE solid gaskets are widely used across chemical plants and are often the default choice for corrosive services.

They are especially common in batch chemical plants, where stainless steel and high-alloy piping systems dominate.

Suitable for High-Grade Materials

For stainless steel or high-alloy piping, PTFE solid gaskets are typically the first option.

One known limitation of PTFE is gas permeation, but this phenomenon also occurs with PTFE envelope gaskets.

In most batch plant services, alternative materials offering better permeation resistance are rarely practical.

Therefore, standardizing on PTFE solid gaskets is usually the most rational approach.

Basic Specifications

PTFE solid gaskets are relatively simple components:

- Material: PTFE (often die-cut from PTFE sheet)

- Temperature: Typically not recommended above ~100 °C (manufacturer dependent)

- Pressure: Around 1.0 MPa, sufficient for most batch plants

- Thickness: Several options, usually standardized within a plant

From a maintenance standpoint, their simplicity is a major advantage.

Filled PTFE (Additives)

Although pure PTFE already offers excellent chemical resistance, additives can improve mechanical performance.

Silica-Filled PTFE

- Improved strength and creep resistance

- Usable up to ~150–200 °C

- Pressure capability up to ~2–3 MPa

A good option when pure PTFE performance is marginal.

Carbon-Filled PTFE

- Improves strength and thermal properties

- Not recommended for strong oxidizing acids (e.g., nitric or sulfuric acid)

- Reduced chemical universality

Alumina-Filled PTFE

- Higher temperature resistance than silica

- Excellent strength

- Higher cost

A reasonable upgrade when silica-filled PTFE is insufficient.

PTFE Envelope Gaskets (Jacketed Gaskets)

General Positioning

PTFE envelope gaskets should be considered special-purpose solutions, not general replacements for PTFE solid gaskets.

Advantages

Lower Cost

Envelope gaskets use less PTFE, making them slightly cheaper.

Improved Compressibility

This is the main advantage.

PTFE itself is relatively stiff.

On fragile flange faces—such as glass-lined or PTFE-lined equipment—a solid PTFE gasket may cause surface damage.

Envelope gaskets deform more easily, allowing better sealing on uneven or delicate surfaces.

Limitations

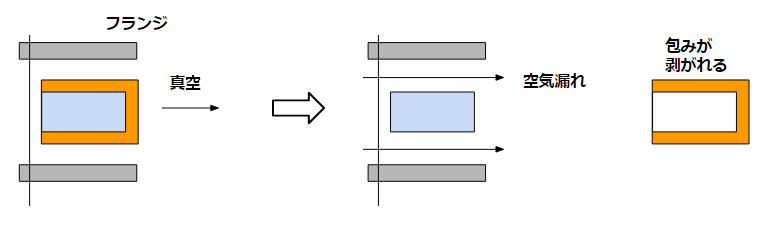

Vacuum Service Requires Care

Under vacuum conditions, the PTFE jacket may be drawn inward, increasing leakage or damaging the gasket.

Countermeasures include sealing the outer edge of the jacket, but this increases cost and complexity.

In many cases, a solid PTFE gasket is simpler and more reliable.

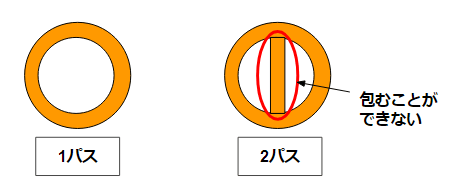

Limited Shape Complexity

PTFE envelope gaskets are difficult to manufacture in complex shapes.

A typical example is a multi-pass heat exchanger tube sheet:

- Single-pass: simple donut shape → possible

- Multi-pass: internal sealing sections → impractical

In such cases, solid PTFE gaskets are generally preferred.

Design Options for PTFE Envelope Gaskets

Inner Diameter Shape

- Standard type: Easy to manufacture, but may create liquid hold-up

- U-shaped (no pocket): Minimizes liquid retention, higher cost

Pharmaceutical and fine chemical plants often prefer the latter.

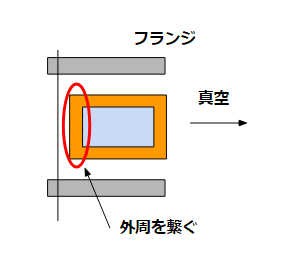

Outer Diameter Sealing

For vacuum service, the outer jacket may be:

- Welded or stitched

- Fully sealed or partially sealed

Fully welded designs offer the best vacuum resistance but at higher cost.

Metal Inserts

A thin stainless steel insert may be added to:

- Improve sealing pressure distribution

- Compensate for flange distortion

This is common for glass-lined or PTFE-lined nozzles, especially on vessels.

Thickness and Dimensions

Changing gasket thickness is difficult once standardized.

Envelope gaskets also introduce an additional variable: jacket thickness, which affects vacuum resistance and permeation.

Dimensions often need adjustment for lined piping, as lining thickness and geometry vary by manufacturer.

Flange and Valve Tolerances

Sealing performance depends not only on piping but also on valve face geometry.

In some systems, the valve defines the effective gasket contact area rather than the pipe flange.

Soft PTFE (Highly Compressible Types)

Purpose and Usage

Soft PTFE gaskets (sometimes called “marshmallow” types) are primarily used for temporary or emergency sealing.

Typical applications include:

- Temporary sealing of leaking flanges

- Sealing pinholes with clamps

- Threaded connections

- Irregular or non-standard shapes

Under mild conditions, they may last longer than expected, but they should be treated as interim solutions until permanent repair.

Atmospheric Pressure Equipment

Soft PTFE is also useful for large atmospheric vessels, where full-pressure flange design is impractical.

In such cases, sealing against very low pressure differentials is sufficient, making soft PTFE an economical option.

Improvised PTFE Envelope Gaskets

As an emergency measure, a compressed sheet gasket can be wrapped with PTFE sealing tape, creating a pseudo-envelope gasket.

While durability is limited, this approach can be practical when:

- Large envelope gaskets are unavailable

- Lead time is critical

Conclusion

PTFE solid gaskets and PTFE envelope gaskets serve different purposes in chemical plants.

- PTFE solid gaskets

Best for flat, rigid flange faces and general corrosion-resistant service. - PTFE envelope gaskets

Suitable for delicate, uneven, or lined surfaces where compressibility is essential.

Understanding these differences allows engineers to select gaskets rationally, improve reliability, and reduce unnecessary variety.

As always, gasket selection should reflect what matters most in your plant—simplicity, durability, or surface protection.

About the Author – NEONEEET

A user‑side chemical plant engineer with 20+ years of end‑to‑end experience across design → production → maintenance → corporate planning. Sharing practical, experience‑based knowledge from real batch‑plant operations. → View full profile

Comments