In many industrial plants, some liquids can freeze or become too thick to flow if the temperature drops. To solve this, engineers use special piping systems to keep fluids warm. The two most common methods are:

- Pipe tracing

- Jacketed piping

Both help with freeze protection and temperature control, but they work differently and are used in different situations.

In this article, we’ll explain the differences in a simple way—so even beginners can understand when and why each method is used.

This post is in a series about pipe

How to Use Pipe Headers in Batch Chemical Plants: A Beginner’s Guide

Upward vs. Downward Pipe Branches: Which One Is Better for Your Plant?

What Is Average Flow Velocity in Pipes? A Simple Guide for Beginners

Why Pipe Supports in Chemical Plants Are Not So “Simple”

How Pipe Diameter Affects Flow Rate: A Simple Guide for Beginners

How to Calculate Flow Rate When Draining Liquid from a Tank Using a Hose

🔌 What Is Pipe Tracing?

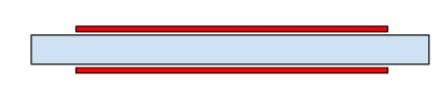

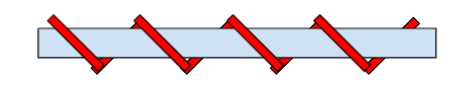

Pipe tracing involves attaching a heat source—usually an electric heating cable or steam tube—to the outside of a regular pipe. The heat source runs alongside the pipe and warms it up.

Types of pipe tracing:

- Electric tracing: Uses electric heating cables

- Steam tracing: Uses small-diameter steam tubes

Common uses:

- Freeze protection in cold weather

- Keeping process lines warm (but not hot)

- Simple or small-scale systems

Pros:

- Easy to install

- Low cost

- Flexible for most pipe sizes

Cons:

- Limited heating power

- May not be enough for highly viscous fluids

🧥 What Is Jacketed Piping?

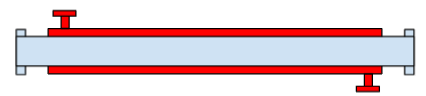

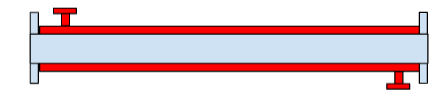

Jacketed piping is a pipe-within-a-pipe system. The product flows through the inner pipe, while a heating medium (like steam or hot oil) flows through the outer jacket.

Common uses:

- High-viscosity fluids (like heavy oil or resin)

- Applications requiring constant high temperature

- Systems that can’t tolerate cold spots

Pros:

- Strong, even heating

- Good for very thick or sticky materials

- Ideal for long-term, stable temperature control

Cons:

- Expensive

- Difficult to install and maintain

- Takes up more space

🔍 Quick Comparison Table

| Feature | Pipe Tracing | Jacketed Piping |

|---|---|---|

| Heating method | Outside heat cable/tube | Surrounding jacket flow |

| Installation cost | Low | High |

| Heating performance | Moderate | Strong |

| Maintenance | Easy | Complex |

| Best for | Freeze protection | Thick or hot materials |

🛠️ Real-World Tip

When designing or reviewing a system:

- Use pipe tracing for water, solvents, or light chemicals in cold weather

- Use jacketed piping for heavy oils, polymers, or materials that solidify easily

- Always check the required fluid temperature and pipe length before choosing

✅ Summary

- Pipe tracing uses external heat sources (like steam or electric cable) to warm the pipe

- Jacketed piping uses a second pipe (jacket) to surround the product pipe with heat

- Tracing is cheaper and easier, good for light heating

- Jackets are stronger but costlier, used for viscous or heat-sensitive fluids

- Choose based on fluid type, temperature need, and budget

Understanding these two heating methods will help you select the right solution for your piping system.

Comments