Mechanical seal leakage is one of the most common and frustrating problems in industrial plants.

Even with preventive measures in place, leaks still happen.

Some engineers accept it as “just the way seals are,” while others struggle to find a reliable fix.

In this article, we’ll explain why mechanical seals leak—focusing on contamination, cooling issues, and operational mistakes—and show practical steps to prevent failures in chemical and process plants.

Essential Guide to Mechanical Seal Support Systems in Chemical Plants

What Is a Gland Packing (Gland Seal)? A Clear Guide to Its Purpose, Mechanism, and Use Cases

Top 3 Mechanical Seal Flushing Plans Explained (API 682 Standards)

Seal Basics for Chemical Plants: How to Prevent Leakage Through Proper Design and Selection

When in Doubt, Choose a Double Mechanical Seal: Practical Reasons for Chemical Plants

What Is a Labyrinth Seal in Chemical Plants?

Why Do Large-Diameter Seals Leak?

How to Select Pumps for Batch Chemical Plants: A Practical Guide for Engineers

Centrifugal Pump Basics: Understanding Structure, Components, and Key Functions

Canned vs. Magnetic‑Drive Pumps: How to Choose the Right Seal‑Less Pump

Basic Guide to Centrifugal Pumps for Beginner M&E Engineers in Chemical Plants

Introduction to Centrifugal Pump Design for Chemical Plants: Applications, Materials, Sealing, and Electrical Specifications

1. Leakage from the Sliding Faces

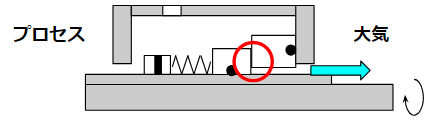

Most seal failures originate from the sliding interface between the rotating and stationary rings.

While secondary seals like O-rings or gaskets can also leak, the majority of failures occur at the mechanical faces.

These surfaces are designed to maintain an extremely tight clearance, allowing a thin film of fluid to lubricate but not leak. When that balance is broken, leakage begins.

2. Contamination and Foreign Particles

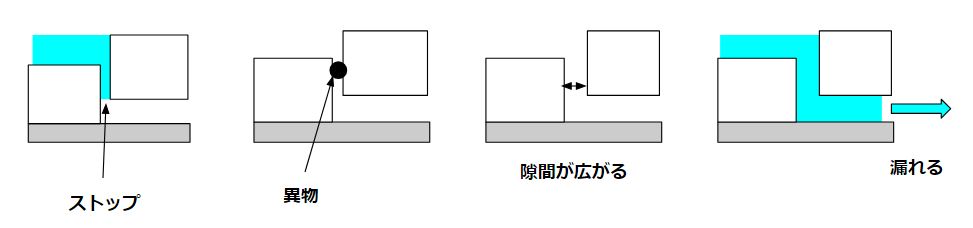

The most common cause of seal leakage is contamination.

Rust, scale, or crystallized solids can enter the seal chamber and scratch the polished sealing faces.

Once scratches develop, the clearance increases and fluid begins to pass through, leading to continuous leakage.

To prevent this:

- Always flush or strain the system before operation.

- Avoid running the pump with dirty or unfiltered fluids.

- Implement temporary strainers during commissioning or after maintenance.

3. Insufficient Cooling

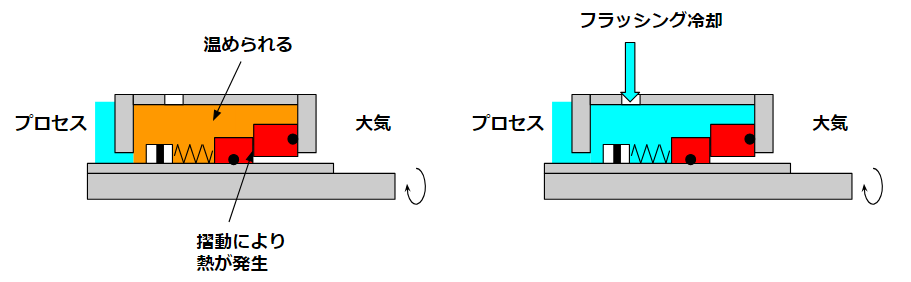

Another major cause of leakage is inadequate cooling.

When the seal faces rotate, friction generates heat.

If the flush or cooling system is not functioning properly, the temperature in the seal chamber rises quickly, reducing lubrication and damaging the seal surfaces.

A well-designed flushing plan (API Plan 11, 21, or 23) ensures continuous cooling and prevents thermal failure.

If the cooling flow stops—even for a short time—the seal can overheat and fail almost instantly.

4. Preventive Measures

✅ Pre-Startup Checks

Before starting up the pump, confirm:

- The pump is installed and aligned correctly.

- Cooling or flushing liquid is flowing properly.

- The suction line has been flushed and cleaned.

Even simple mistakes—like a closed cooling valve—can lead to seal failure within minutes of startup.

🔧 Regular Maintenance

Mechanical seals are wear components and require periodic replacement.

Follow time-based (TBM) or condition-based (CBM) maintenance programs, replacing seal faces, sleeves, and O-rings before serious wear occurs.

💧 Choosing the Right Cooling Liquid

Selecting a proper cooling or barrier fluid is critical:

- For most systems, ambient-temperature water works fine.

- For sensitive processes, use compatible solvents or brine instead of water.

- For high-temperature or crystallizing fluids, consider double mechanical seals with an external cooling circuit.

In batch operations, improper cooling can cause boiling, crystallization, or freezing, all of which severely damage seals.

🌡️ Don’t Forget Insulation

Some engineers overlook insulating the seal chamber, assuming it’s unnecessary.

However, for processes that crystallize below 70–80°C, insulation is vital to prevent the seal area from overcooling and forming solids.

Balance insulation with proper cooling—check flow rates frequently to avoid clogging.

🧼 Post-Operation Cleaning

After each operation—especially in batch systems—flush the pump and seal area with clean liquid.

You can:

- Circulate cleaning fluid from the tank to the pump suction line, or

- Add a dedicated cleaning line to the suction side.

Even if your process liquid appears clean, contaminants or crystallization can occur unexpectedly.

A consistent cleaning procedure is the simplest way to extend seal life.

🧭 Conclusion

Most pump seal failures come down to foreign particles or cooling issues.

By performing proper startup checks, regular maintenance, and coolant management, you can dramatically reduce leakage incidents.

For every process, tailor your approach—coolant type, insulation, and cleaning frequency—to the specific operating conditions.

About the Author – NEONEEET

A user‑side chemical plant engineer with 20+ years of end‑to‑end experience across design → production → maintenance → corporate planning. Sharing practical, experience‑based knowledge from real batch‑plant operations. → View full profile

Comments