A labyrinth seal is a non-contact sealing method widely used in rotating machinery in chemical plants.

By avoiding direct contact, it prevents wear while still reducing leakage of gases or liquids.

When engineers think about seals for rotating equipment, mechanical seals usually come to mind first.

Before them, there were gland packings, and beginners often assume that there are essentially no other options.

That understanding is not wrong.

However, it is still useful to remember — even occasionally — that labyrinth seals exist as an alternative.

In this article, we explain the basic structure, operating principle, advantages, and limitations of labyrinth seals in a practical and easy-to-understand way.

This information is useful for maintenance staff, mechanical engineers, and piping engineers.

Essential Guide to Mechanical Seal Support Systems in Chemical Plants

Why Mechanical Seals Leak in Pumps — and How to Fix It

Top 3 Mechanical Seal Flushing Plans Explained (API 682 Standards)

Seal Basics for Chemical Plants: How to Prevent Leakage Through Proper Design and Selection

When in Doubt, Choose a Double Mechanical Seal: Practical Reasons for Chemical Plants

What Is a Gland Packing (Gland Seal)? A Clear Guide to Its Purpose, Mechanism, and Use Cases

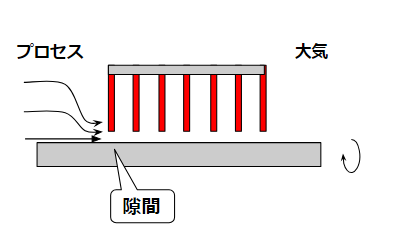

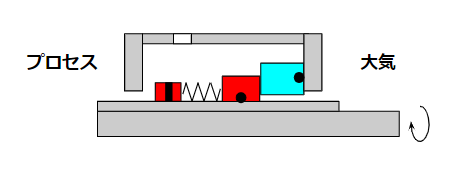

Structure and Operating Principle of Labyrinth Seals

Let’s start with the basic structure of a labyrinth seal.

A labyrinth seal is an imperfect seal that consists of multiple clearances arranged in a complex path.

The word labyrinth literally means maze.

If a maze is narrow and complicated, escaping from it is difficult.

The same idea applies to fluids (liquids or gases) in rotating machinery — it becomes difficult for them to pass through the maze-like gaps.

Unlike mechanical seals, a labyrinth seal does not provide a perfect seal.

However, it can still achieve sufficient sealing performance for certain applications, which is its key feature.

Mechanical seals also have clearances, but those gaps are extremely small.

Because liquid leakage to the outside is effectively prevented, they are often described as “perfect seals.”

Gland packings follow the same basic principle: reducing leakage by minimizing clearances.

メカニカルシール

Where Labyrinth Seals Are Used in Chemical Plants

In chemical plants, the use of labyrinth seals is very limited.

They are typically applied only to:

- Fans, blowers, and air-handling equipment

- Systems where leakage to the atmosphere is acceptable

- Systems where air or water ingress is not a problem

This is almost the only practical application.

The greatest advantage of labyrinth seals is that they are virtually maintenance-free compared to mechanical seals or gland packings.

However, situations where this advantage can be used in chemical plants are surprisingly few.

Labyrinth seals provide moderate sealing performance.

If used for liquids, leakage is very likely unless the design is extremely careful.

This contradicts the “dry floor” concept often emphasized in TPM (Total Productive Maintenance).

Even when used for gases, the design assumes contact with ambient air.

Therefore, applications are effectively limited to fans and blowers.

Cases where labyrinth seals should NOT be used

Labyrinth seals should be avoided when:

- Toxic gases must not be released to the atmosphere

- Ingress of air or water could cause reactions or increase corrosivity

In chemical plants, blowers are often designed under the assumption that the handled gas is “air.”

This is acceptable for power calculations, but it can be insufficient for material selection and seal design.

If plant-generated gases are mixed into the air stream, this must be considered.

When using labyrinth seals, it is assumed that upstream gas treatment is already in place.

If leakage occurs at the labyrinth seal, the entire safety concept collapses.

If upstream treatment is insufficient or higher safety is required, gland packings are often a better choice — assuming contamination from packing debris is acceptable.

Simple Is Best

The operating principle of a labyrinth seal is extremely simple.

Even compared to gland packings, its structure is simpler.

Simply providing appropriate clearances can deliver a certain level of sealing performance.

If damage occurs, repair or temporary fabrication is relatively easy.

Of course, if higher performance is required, detailed analysis and optimization are necessary.

But this increases structural complexity and makes repairs more difficult.

At that point, the original advantage of labyrinth seals — simple structure with reasonable performance — is lost.

Why the “Labyrinth Concept” Matters

Labyrinth seals themselves are rarely used in chemical plants, but the concept behind them is very important.

Even with a simple structure, increasing pressure loss can create a sealing effect.

This idea can be applied beyond shaft sealing.

Examples include:

- Temporary countermeasures when a seal has failed and gas is leaking

- Low-cost improvements to working environments in powder-handling areas

- Controlling gas flow to reduce corrosion in piping caused by reaction gases

The idea of controlling flow by increasing pressure loss is an important engineering mindset in process and plant design.

It may lead to surprisingly simple solutions to on-site problems.

Conclusion

We have explained why labyrinth seals are used in chemical plants.

In practice, their application is limited to fans and blowers where air or water ingress is acceptable.

Places where a “moderate seal with no maintenance” is both acceptable and beneficial are fewer than expected.

However, the concept of using pressure loss to control flow is widely applicable and worth remembering.

Comments