In chemical plants, especially multi-purpose batch plants, flexibility is everything.

New products are often added after start-up, and piping systems must adapt without major redesign or safety risks.

One important but often overlooked design choice is the material of piping headers.

This article explains why using glass-lined piping for headers is a smart and practical design rule in batch plants, focusing on expandability, corrosion risk, and ease of piping design.

Batch Plants Are Designed to Change

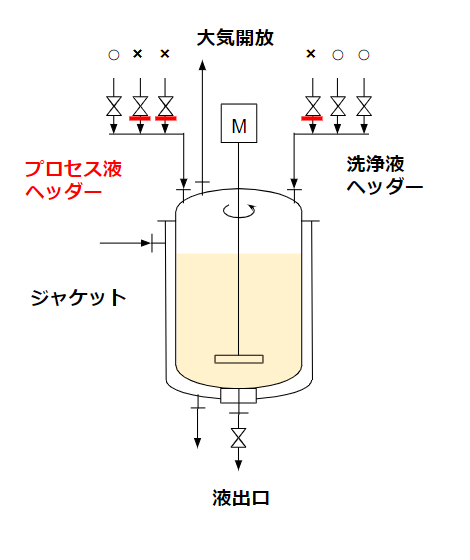

A piping header is used to connect multiple pipes to equipment such as tanks or pumps.

In single-product plants, one dedicated line may be enough.

However, in multi-purpose batch plants, headers are essential because:

- Products have different destinations

- The same equipment is reused for different processes

- Flow paths are frequently switched

This means that future expansion is not an exception—it is expected.

Stainless Steel Headers Are Hard to Modify

For a single, fixed product, a custom-made stainless steel header may work well.

But in batch plants, new products are often introduced after construction.

If the header is made of stainless steel, adding new branches usually requires:

- Removing the existing header

- Fabricating a new one

- Cutting and welding used piping

This increases not only modification cost but also safety risks, such as chemical exposure, fire, or gas release from used pipes.

Glass-Lined Headers Are Easy to Expand

Glass-lined piping systems are modular.

When headers are built using glass-lined tee pieces, expansion becomes simple.

You can extend the header by:

- Adding a tee at the end

- Connecting new lines without touching existing ones

This minimizes modification work and significantly reduces operational risk—making glass-lined headers ideal for batch plants.

⚠️ One note: if the end of the header is used as a solvent flushing line, adding branches may affect that function and should be reviewed carefully.

Reduced Corrosion Risk Across Products

Another major advantage of glass-lined headers is corrosion resistance.

In practice, designers may assume:

“This header only handles water, so stainless steel is fine.”

But problems occur when:

- Reactive gases reach the header

- A different product is introduced later

- Existing headers are reused without full material review

Once a header is installed, material checks tend to be skipped.

Using glass-lined headers from the start eliminates this risk across all products and operating conditions.

Standardization Makes Piping Design Easier

Glass-lined piping components have fixed standard dimensions.

At first glance, this seems restrictive—but it actually helps designers.

Because dimensions are fixed:

- Header length is automatically determined

- Equipment layout becomes clearer

- Piping routes have a natural reference

Compared to carbon steel or stainless piping, where anything can be adjusted, glass-lined headers reduce design choices and simplify layout decisions—especially helpful for less-experienced designers.

Conclusion

In multi-purpose batch plants, piping headers must be:

- Easy to expand

- Safe to modify

- Resistant to corrosion under changing conditions

- Simple to design and review

From this perspective, glass-lined piping is an excellent choice for headers.

Instead of optimizing only for initial cost, designing headers with future changes in mind leads to safer, more flexible, and more reliable batch plants.

Comments