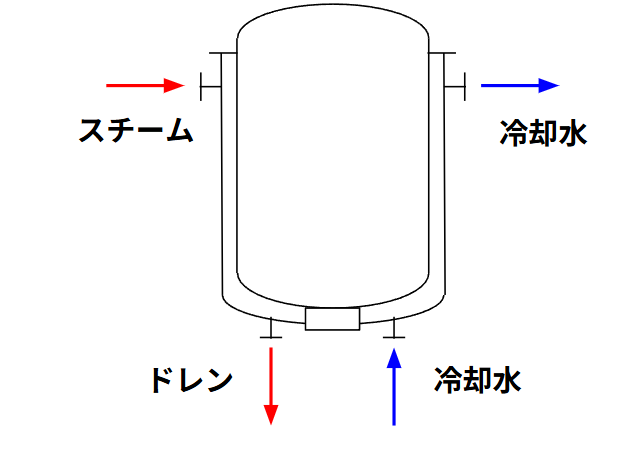

In chemical plants, cooling water is widely used in shell-type heat exchangers and jacketed vessels.

While equipment may operate without issues at the beginning, heat transfer performance inevitably deteriorates over years of operation.

The real problem is that this degradation progresses slowly.

As a result, decisions are often postponed with thoughts like “It’s still acceptable” or “It’s not urgent yet”.

By the time the problem becomes visible—such as temperature deviations or leakage—the situation may already be critical.

This article focuses on problems that inevitably occur when cooling water is used, regardless of the process fluid.

We explain how fouling factor increases lead to performance loss, higher energy costs, and ultimately equipment damage.

We also discuss the realistic limitations of cleaning and water quality improvement, and how to think about long-term maintenance decisions in chemical plants.

Is the Shell-and-Tube Heat Exchanger the Best Choice for Batch Plants? A Practical Selection Guide

Shell-and-Tube Heat Exchangers Made Simple: A Beginner’s Design Guide for Chemical Plants

A Complete Guide to Shell and Tube Heat Exchangers: Key Parts and Structure Explained for Beginners

Water Is Dirty — A Reality Designers Often Don’t Feel

Operators and maintenance engineers with long experience instinctively know that “water is dirty.”

However, even designers often lack a tangible sense of this reality.

When imagining a shell-side or jacket-side cooling water system, it is easy to picture clean water flowing continuously and heat exchange remaining optimal.

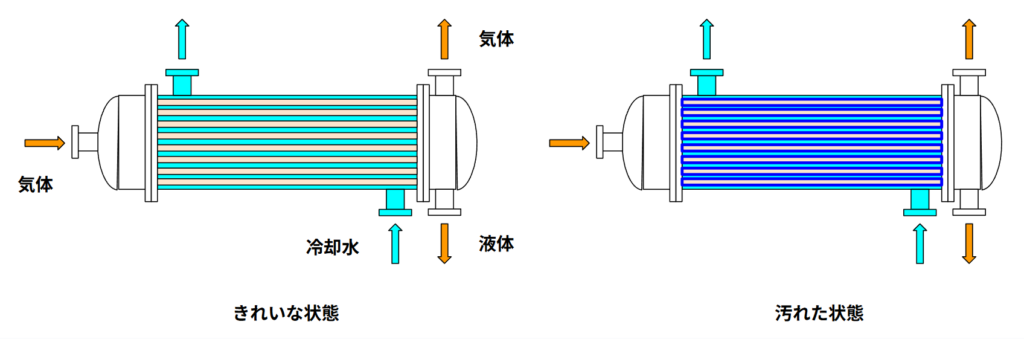

In reality, as long as cooling water is used, rust and insoluble solids gradually adhere to surfaces, increasing the fouling factor on the cooling water side.

From a heat transfer perspective, this means that the effective thermal resistance increases—

essentially, the heat transfer wall becomes thicker.

This phenomenon is unavoidable and occurs in both shell-type heat exchangers and jacketed equipment.

Performance Loss Caused by Fouling Factor Increase

As fouling accumulates, heat exchanger performance declines.

Let’s evaluate this quantitatively.

Assume the fouling factor on the cooling water side increases from

0.0004 to 0.0006 m²·hr·K/kcal.

This change alone can reduce the overall heat transfer coefficient by approximately 20%.

Although this may seem minor numerically, the impact is significant in practice.

As fouling builds up:

- Effective heat transfer area decreases

- Cooling water velocity increases

- Pressure loss increases

In practice, it is more practical to treat these effects collectively as a drop in the overall heat transfer coefficient, rather than analyzing each factor in detail at the field level.

Energy Cost Perspective

To compensate for a 20% drop in performance, suppose cooling water flow rate is increased by 20%, resulting in a 20% increase in pump power.

Example assumptions:

- Pump power: 30 kW → 36 kW

- Electricity cost: 30 JPY/kWh

- Operating time: 8,000 hours/year

This results in an additional 1.44 million JPY per year in electricity costs.

For a plant producing 100 tons per year, this corresponds to approximately

14.4 JPY/kg as an added variable cost.

Whether this cost is acceptable or not becomes a key decision point.

What Happens If Fouling Is Ignored

Process Temperature Increase

As fouling reduces cooling water flow paths, sufficient cooling becomes impossible.

In liquid–liquid heat exchangers, this often appears as an increase in outlet temperature and may be detected by alarms.

In condensers, however, abnormal conditions are not always immediately apparent, making detection more difficult.

Leakage and Equipment Failure

Over long periods, repeated rust formation and peeling gradually reduce wall thickness.

Eventually, shells or jackets—often made of carbon steel such as SS400—may fail under pressure.

Even though the fluid is “only cooling water,” leakage in a chemical plant is difficult to repair.

Welding repairs are rarely simple or safe in operating facilities.

In shell-and-tube exchangers, tube-side failure may also occur.

This is largely due to thickness differences: tube-to-shell thickness differences are generally smaller than those between vessel shells and jackets.

Countermeasures and Their Limitations

Making Cooling Water Clean Is Not Easy

A natural reaction is to think: “If cooling water is dirty, just clean it.”

While technically possible, improving water quality requires significant cost.

Cooling water is typically managed with a strong focus on cost reduction.

Although industrial water can be treated to produce cleaner water, ongoing makeup water requirements make this expensive.

In many cases, plants rationally conclude that using equipment until failure and then replacing it is more economical.

Cleaning Is Also Expensive

Consider a cleaning cost of 5 million JPY per unit.

If a plant has 50 heat exchangers and cleans two per year, each unit is cleaned once every 25 years.

At the plant level, this corresponds to approximately 10 million JPY per year in maintenance costs.

For a plant producing 100 tons annually, this adds roughly

100 JPY/kg to fixed costs.

Even with cleaning, extending equipment life from 40 to 50 years may be the best-case scenario.

Given that replacement costs can exceed 10 million JPY per unit, maintenance decisions must be evaluated calmly and quantitatively.

Conclusion

When cooling water is used, fouling is unavoidable.

Increased fouling leads directly to:

- Reduced heat transfer performance

- Higher energy costs

- Increased risk of equipment failure

The key question is not simply “Should we clean?” or “Should we improve water quality?”

Instead, the correct approach is to balance cost, equipment life, and risk.

Heat exchanger maintenance should be based on long-term, rational decision-making, not short-term efficiency alone.

About the Author – NEONEEET

A user‑side chemical plant engineer with 20+ years of end‑to‑end experience across design → production → maintenance → corporate planning. Sharing practical, experience‑based knowledge from real batch‑plant operations. → View full profile

Comments