In liquid–liquid phase separation systems, conductivity meters are often used to detect the boundary between the aqueous phase and the organic phase. However, in real chemical plants, conductivity sensors frequently fail to touch the liquid, show unstable readings, or respond incorrectly due to gas pockets and improper piping design.

This article explains the essential design points for installing a conductivity meter in a phase-separation line, focusing on full-pipe conditions, piping geometry, and flow-velocity control.

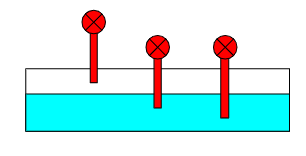

1. Reliable Measurement Requires Continuous Liquid Contact

A conductivity sensor only works when the probe is fully in contact with the liquid.

In phase-separation lines, the difference in conductivity between the oil phase and the water phase is large, so the sensor must stay within the liquid at all times.

Common real-world issues include:

- the line is not running full

- gas accumulates on the upper side of the pipe

- no sight glass is available to confirm liquid coverage

- the sensor ends up in the gas layer during operation

Because of this, the piping must be designed so that the sensor tip is always in the liquid stream, not in the gas space.

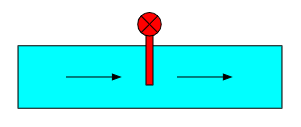

2. Installing Sensors in Horizontal Piping: The Risk of Gas Pockets

Conductivity meters are usually installed on the side of horizontal pipes.

The ideal condition is a fully flooded line, allowing the sensor to remain submerged.

But in practice:

- gas accumulates at the top of the line

- gas enters from the upstream tank

- poor slope or poor routing creates dead zones

To maintain a full-pipe condition, designers should:

- avoid geometries that trap gas

- use gravity flow from the upper vessel to push liquid into the line

- prevent gas backflow from the downstream vessel

These concepts are similar to drop-line design principles in batch chemical plants.

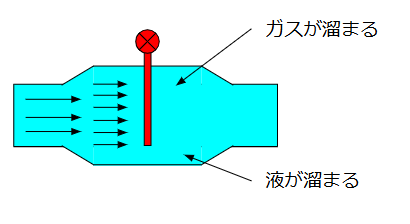

3. Lowering the Flow Velocity: Larger Pipe Diameter Is Not Always Safe

Conductivity readings are more stable at lower flow velocities.

However, phase separation lines often need faster flow to shorten batch time.

A common approach is to increase the local pipe diameter around the sensor to reduce velocity.

But this solves one problem while creating others:

- gas tends to accumulate at the enlarged upper section

- liquid pools at the bottom, creating unstable two-layer flow

- allowing gas pockets worsens liquid buildup, and vice versa

As a result, oversized sections can reduce separation quality and make measurement less reliable.

Flow, gas behavior, and pipe volume must be balanced carefully.

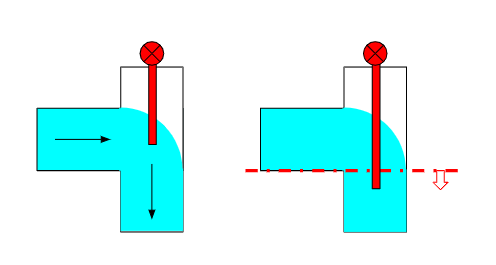

4. Using an Elbow as the Installation Point: More Unpredictable Than It Looks

Sometimes designers place the sensor on an elbow to minimize straight-run length.

However, elbows introduce additional risks:

- the actual liquid-flow area is narrower than expected

- gas distribution is unpredictable

- the sensor may still miss the liquid stream

To ensure contact, designers often need to place the sensor deeper and lower than in a straight run.

This increases sensor length and required installation height, which can impact:

- building height limitations

- interference with nearby lines

- pump and reactor nozzle layouts

- overall plant-layout philosophy

For these reasons, elbow installations must be evaluated carefully—not assumed to be a shortcut.

Conclusion

Accurate conductivity measurement in phase-separation systems depends on one fundamental requirement: the sensor must always be submerged.

To achieve this, engineers must carefully consider:

- maintaining full-pipe conditions

- avoiding gas pockets and liquid holdup

- balancing flow velocity and pipe size

- the risks of using elbows as sensor installation points

Most “faulty” readings are caused not by the instrument but by the piping design.

Understanding phase-separation behavior and designing lines that ensure continuous liquid contact is essential for stable operation.

Comments