In chemical plants, even a small backflow in a process line can cause serious contamination, damage equipment, or compromise product quality.

While manual and automated valves can control flow, they require human operation or power sources.

Check valves, on the other hand, are simple, automatic, and require no external power, making them a key safety component in any piping system.

However, not all check valves are created equal. Choosing the wrong type—or installing it incorrectly—can completely defeat its purpose.

This guide explains the basic types of check valves used in chemical plants, their characteristics, and how to select the right one for your application.

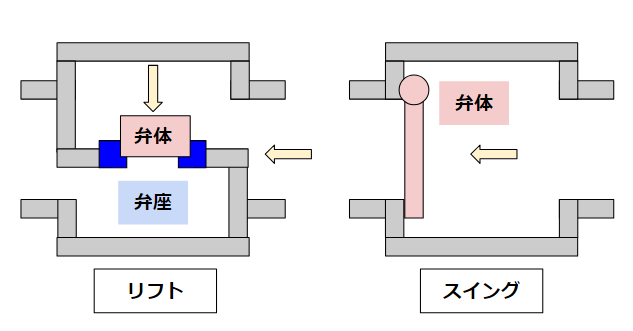

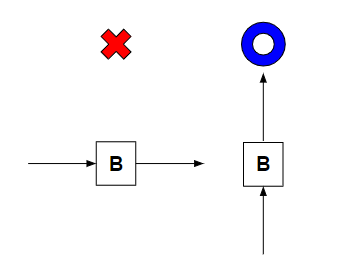

1. Lift vs. Swing Check Valves

The two most common types are lift and swing check valves.

Here’s a quick comparison:

| Feature | Lift Type | Swing Type |

|---|---|---|

| Installation direction | Horizontal only | Horizontal or vertical |

| Suitable size range | Small sizes | Small to large |

| Pressure loss | Higher | Lower |

| Sealing performance | Excellent | Moderate |

| Durability | Long | Moderate |

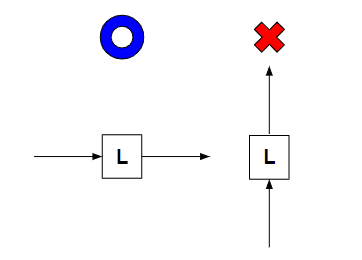

Lift check valves operate by moving a disk vertically to open or close the flow path.

Because the disk moves against gravity, they only work properly in horizontal pipelines.

In vertical lines, gravity interferes with movement, causing poor sealing or even malfunction.

Swing check valves, on the other hand, use a hinged disk that swings open with the flow.

They work in both horizontal and vertical orientations, making them more versatile.

While their sealing performance is not as tight as lift types, swing valves are suitable for larger pipe sizes and lower pressure losses.

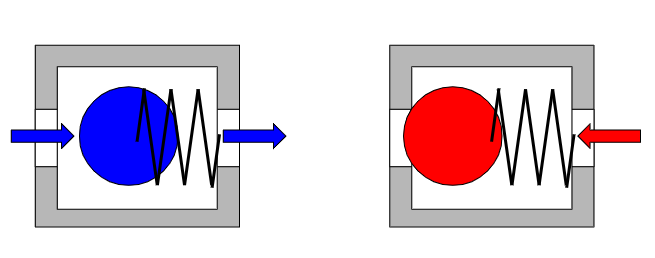

2. Ball Check Valves

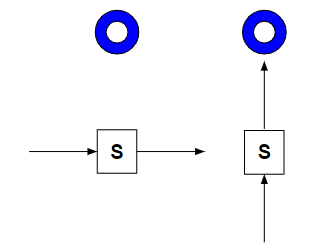

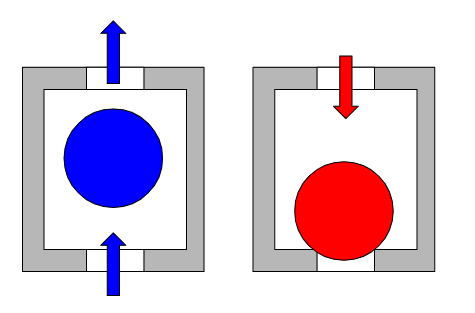

A ball check valve uses a free-moving ball that shifts with the flow.

When fluid flows in the correct direction, the ball lifts; when the flow reverses, gravity or pressure pushes the ball back into its seat, sealing the passage.

Unlike the lift type, the ball moves in the same direction as the flow, meaning this design can only be used in vertical pipelines.

Its greatest advantage is that lining materials (e.g., glass or PTFE) can be applied, offering excellent corrosion resistance, making it ideal for acidic or corrosive services.

However, because flow direction is limited, it can cause liquid accumulation or dead zones in the system.

3. Spring-Loaded Check Valves

To overcome gravity limitations, some ball-type valves use springs to control movement.

This allows for flexible installation—horizontal or vertical—without relying on gravity.

While this seems ideal, spring-loaded valves can be unreliable in corrosive environments.

Springs may corrode, break, and release fragments into the process stream, risking equipment damage or contamination.

In chemical plants, this failure risk often outweighs the design benefits.

For this reason, many engineers prefer simpler mechanical designs like lift or swing types.

Summary

Choosing the right check valve is essential for safe and efficient plant operation.

| Type | Key Advantages | Limitations |

|---|---|---|

| Lift | Tight sealing, long life | Horizontal only, small sizes |

| Swing | Flexible orientation, low loss | Larger footprint, lower sealing |

| Ball | Corrosion-resistant, simple | Vertical only, possible dead zones |

| Spring | Any direction | Poor corrosion durability, maintenance risk |

Even though spring-loaded valves appear convenient, simplicity and reliability often win in the demanding environments of chemical plants.

Comments