Centrifugal pumps are widely used in chemical plants and factories to efficiently transfer liquids.

Yet, many engineers who use them daily have only a vague idea of how the internal parts actually work together.

This article explains the main components and structure of a centrifugal pump—from casing and impeller to seals and bearings—so that even beginners can clearly understand how each part functions.

Whether you’re working in plant design or maintenance, understanding pump construction is essential.

Even if your role is more of a “coordinator” than a hands-on technician, knowing what’s inside the pump helps you make better decisions and communicate more effectively with mechanical engineers.

Why Mechanical Seals Leak in Pumps — and How to Fix It

How to Select Pumps for Batch Chemical Plants: A Practical Guide for Engineers

Canned vs. Magnetic‑Drive Pumps: How to Choose the Right Seal‑Less Pump

Basic Guide to Centrifugal Pumps for Beginner M&E Engineers in Chemical Plants

Introduction to Centrifugal Pump Design for Chemical Plants: Applications, Materials, Sealing, and Electrical Specifications

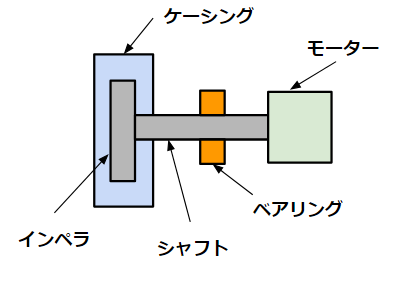

🌀 1. Basic Structure of a Centrifugal Pump

A centrifugal pump transfers energy from a motor to a liquid through a rotating impeller inside the casing.

The impeller adds velocity to the fluid, which is then converted to pressure as it moves through the casing.

The shaft connects the impeller to the motor, while bearings support the shaft’s rotation.

Understanding this simple energy transfer structure is the foundation of pump design.

⚙️ 2. Pump Internal Components

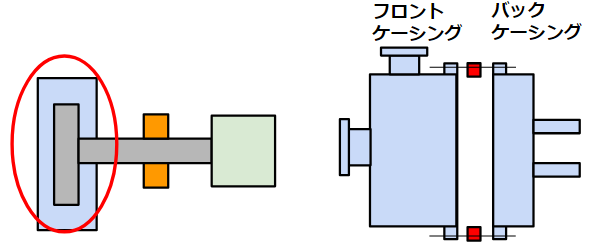

Casing

The casing is the main body of the pump that contains the liquid.

Inside it, the impeller spins and imparts energy to the fluid, increasing its pressure.

Casing structures are typically divided into two parts:

- Front casing (process side)

- Back casing (motor side)

Between these two parts, sealing materials such as O-rings or gaskets prevent leakage.

While detailed CAD models are useful, it’s more important for engineers to visualize each part’s purpose.

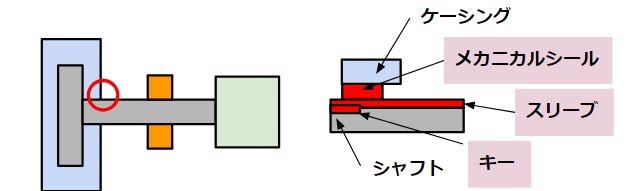

Mechanical Seal

The mechanical seal prevents leakage between the rotating shaft and the stationary casing.

Since the shaft must rotate freely while the casing stays fixed, a high-performance sealing device is required.

The typical structure includes:

- Shaft

- Mechanical seal

- Casing

- (Optional) Sleeve to protect the shaft from wear

The sleeve rotates with the shaft using a key connection, allowing easy replacement during maintenance.

In chemical plants, where corrosion resistance is crucial, mechanical seals and sleeves are almost always used.

⚙️ 3. Drive-Side Components

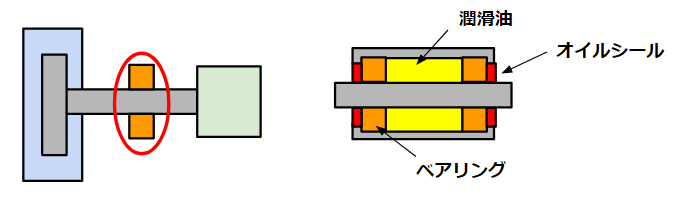

Bearings

Bearings are essential for smooth and stable rotation.

In small or standard centrifugal pumps, the impeller is usually overhung, supported by bearings only on the motor side.

Bearings are installed inside a bearing housing filled with oil or grease for lubrication.

Oil seals protect against dust and moisture, preventing premature failure.

Some compact pump models rely solely on motor-side bearings, with no independent bearing assembly.

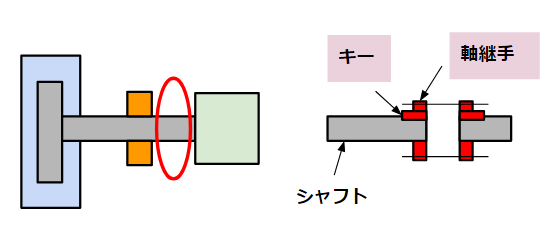

Coupling

The coupling connects the motor shaft to the pump shaft.

Since motors are often purchased as external components, the coupling ensures proper power transmission between two separate shafts.

A key locks the coupling and shaft together, allowing torque transfer.

Both the coupling and the key are wear parts, so they should be checked and replaced during regular maintenance.

🧩 4. The Importance of Technical Terminology

In plant engineering, knowing the correct terminology is part of being professional.

Using accurate terms speeds up communication and avoids misunderstandings.

Trying to explain everything through pictures alone often slows work down.

Get familiar with essential terms—impeller, casing, mechanical seal, bearing, coupling—and use them naturally in daily discussions.

Summary

Understanding the structure and components of a centrifugal pump is the first step toward safe and efficient operation.

Key takeaways:

- Learn the basic structure: impeller, casing, seal, bearing, coupling

- Know what each component does and how they interact

- Use proper terminology in communication and documentation

Even simple pumps hide mechanical insights that can make your work as an engineer smoother and safer.

About the Author – NEONEEET

A user‑side chemical plant engineer with 20+ years of end‑to‑end experience across design → production → maintenance → corporate planning. Sharing practical, experience‑based knowledge from real batch‑plant operations. → View full profile

Comments