For mechanical engineers and equipment personnel working in chemical plants, welding may feel outside your expertise. However, basic welding knowledge is essential for piping design, maintenance, and troubleshooting.

This article explains, in a practical and easy-to-understand way, the types of welding you should know, precautions, and common on-site issues—even if you are not a welding specialist. You don’t need to memorize everything, but recognizing the overall scope and depth of welding knowledge is a good starting point.

Welding Repair Methods: A Beginner’s Guide to Choosing the Right Technique

Five Reasons Acetylene Is Chosen and Key Handling Precautions [For Chemical Plants]

Welding Types

Typical welding types include:

- SMAW – Shielded Metal Arc Welding

- GTAW – TIG Welding

- Plasma Arc Welding

- MIG – Metal Inert Gas Welding

- MAG – Metal Active Gas Welding

- FCAW – Flux-Cored Arc Welding

- SAW – Submerged Arc Welding

Among these, SMAW (for steel) and GTAW (for stainless steel) are the most essential for chemical plants.

Shielded vs Gas-Shielded Arc

- SMAW uses a coated electrode to block air.

- GTAW uses an external gas shield (typically argon).

Both prevent contamination from air (oxygen, nitrogen) during welding.

Manual, Semi-Automatic, and Automatic Welding

- Manual: performed entirely by hand.

- Semi-Automatic: machine automatically feeds the rod.

- Automatic: machine performs full welding, typically for large tanks.

Automatic welding reduces the need for advanced skill and ensures consistent quality.

Weld Design

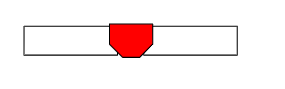

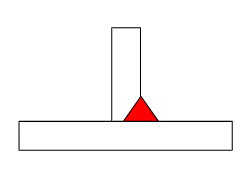

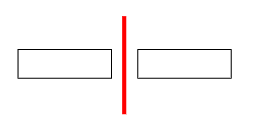

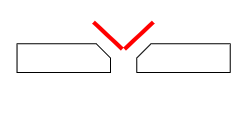

- Butt welds: join two metals edge-to-edge; used for tanks.

- Fillet welds: join metals at right angles; used for nozzles or flanges.

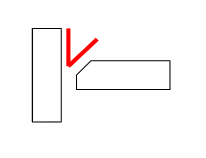

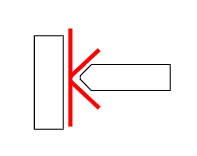

- Shapes: I, V, L, K

- I/V = butt welds

- L = fillet weld 90°

- K = fillet weld for thick plates

Weld thickness should be equal to or greater than base material thickness to maintain strength. For fillet welds, the throat thickness represents weld thickness.

WPS and PQR

- WPS (Welding Procedure Specification): instruction sheet for performing welds.

- PQR (Procedure Qualification Record): test record confirming the method works.

PQR is tested on sample pieces, and WPS follows it on actual production. Non-destructive tests then confirm weld quality.

Common Weld Defects

- Blowholes

- Slag inclusion

- Lack of penetration

- Undercut / overlap

- Cracks (low/high temperature)

Prevention: select proper materials, keep rods dry, maintain correct posture, manage groove shape, and plan weld sequence.

Heat History and Post-Weld Treatment

Welding adds heat to the metal, affecting surrounding areas (heat-affected zone). Avoid re-welding these areas if possible.

- Annealing / Normalizing / Tempering: control cooling rate to avoid weakening metal.

Stainless Steel Sensitization

- Austenitic stainless contains C, Cr, Ni. Welding can cause C to react with Cr or Fe, forming grain boundary precipitates.

- Use low-carbon grades (SUS304L, SUS316L) to reduce risk.

- Choose rods with slightly higher Cr/Ni content than base metal.

Health and Safety

- Arc eye: wear protective shields.

- Electric shock: properly ground welding equipment.

- Fire / explosion: avoid sparks near flammable gases or liquids.

Conclusion

Welding knowledge is essential for chemical plant mechanical engineers—not to become a specialist, but to understand the basics for design, maintenance, and safety. Focus on the main types (SMAW and GTAW), basic design rules, common defects, and safety precautions.

About the Author – NEONEEET

A user‑side chemical plant engineer with 20+ years of end‑to‑end experience across design → production → maintenance → corporate planning. Sharing practical, experience‑based knowledge from real batch‑plant operations. → View full profile

Comments