Asbestos remains a major concern in many industries — and chemical plants are no exception.

Older plants often contain asbestos-insulated pipes and equipment, creating serious health and environmental risks during renovation or decommissioning.

This article summarizes what plant owners and engineers should be aware of when removing asbestos-containing equipment in chemical facilities.

1. Identifying Where Asbestos Is Used

Before starting any removal work, it’s essential to identify where asbestos may exist in your plant. Common locations include:

- Pipe insulation

- Equipment insulation

- Building materials

Among these, pipe insulation poses the highest removal frequency since piping is often replaced or modified.

For owners and engineering managers, high-risk areas such as process equipment or buildings should already be mapped and documented.

However, because of the large number of pipes in chemical plants, identifying every asbestos-containing section can be challenging and often unrealistic.

2. Safe Work Environment and Protection

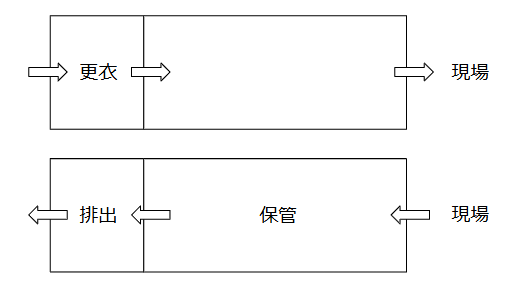

When removing asbestos-insulated pipes, creating a controlled work environment is critical.

Workers must wear protective gear and operate within temporary containment booths designed to prevent asbestos release.

While entering the booth is straightforward, exiting poses higher risk — contaminated protective clothing and materials must be isolated and properly disposed of.

Even with good containment design, complete isolation from asbestos is nearly impossible.

Temporary showers or washing systems may help, but their installation requires careful planning within the plant.

Ventilation fans are often installed in the booth, but their exhaust should never release asbestos fibers directly to the atmosphere. Instead, use water filtration or wet scrubbing systems to capture airborne dust.

When dismantling the temporary booth after the work, remember: it’s not about achieving “zero risk” — it’s about reducing exposure as much as reasonably possible.

3. Communication and Coordination

Once the asbestos removal schedule is fixed, inform all stakeholders within and around the plant.

This includes operators, contractors, inspection teams, and even nearby facilities.

Even if no external release occurs, notifying everyone about possible asbestos work prevents confusion and builds trust in the safety process.

4. Removal Techniques

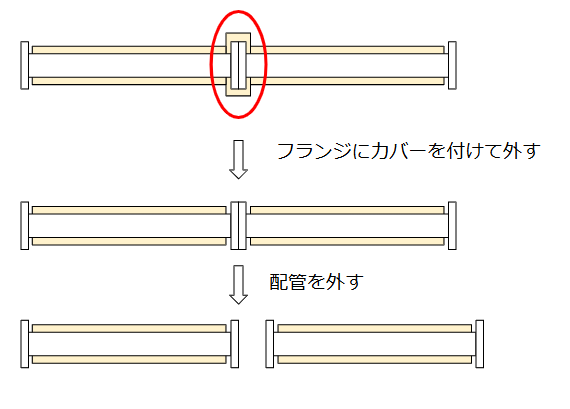

During the removal process, avoid unnecessary disturbance of asbestos materials.

For example, remove only the asbestos-containing flange covers on-site, and transport the pipe section to a safe area for full insulation removal.

Use plastic bags or glove boxes to contain fibers during dismantling.

Even with these methods, some fiber release is inevitable — so continuous water spraying may help, though excessive moisture can cause insulation detachment.

When transporting asbestos-insulated pipes out of the plant, seal both pipe ends in plastic to prevent fiber leakage.

This approach is similar to safe process piping removal methods used in general plant maintenance.

5. Long-Term Planning

Asbestos removal is not a one-time job — it requires a phased, long-term plan.

Even after identifying all sources, securing the necessary budget can be difficult.

Start by prioritizing high-risk areas, while performing temporary repairs on sections that can’t be immediately removed.

Keep in mind that asbestos removal costs are rising each year.

Establishing a long-term financial and risk management framework will help your plant stay compliant and safe over time.

🧩 Conclusion

Asbestos removal in chemical plants demands careful planning, worker protection, and transparent communication.

By identifying high-risk areas early, ensuring a safe work environment, and developing a long-term removal strategy, plant owners can minimize health risks while maintaining operational safety.

Comments