When working in a chemical plant, tanks are one of the first types of equipment you should understand.

However, tank-related terminology—such as main components, accessories, and insulation—can feel overwhelming for new employees and beginners.

In this article, we organize and explain commonly used tank structure terminology from a practical, field-oriented perspective.

We focus only on the terms you really need to understand to work effectively.

Essential Tank Terminology for Chemical Engineers|Master the Words Used in Real Plant Design

9 Common Tank Nozzle Design Patterns for Chemical Plants

Tank Nozzle Orientation: Practical Guidelines for Design and Operation

Pressure Testing in Tanks and Piping: Understanding Leak, Hydrostatic, and Water-Filling Tests

Understanding Design Pressure in Chemical Plant Tanks: A Practical Guide

Why Tanks Cannot Be Fully DrainedOperational Issues Caused by Dead Volume and Practical Countermeasures

Designing Tank Manholes: Key Points for Safety and Maintenance Efficiency

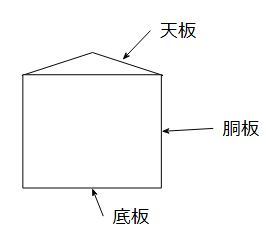

Names of Main Components

For tank main components, metal plates are the most important elements to understand.

Since tanks are constructed from metal plates, plate-related terminology is critical.

The naming rule is simple: tanks are divided into top, shell, and bottom.

Plates

Sometimes these are called upper, side, and lower plates, but the concept is the same.

The terms themselves may sound simple, and if you only hear them without seeing the kanji, they can be confusing at first.

These three plates are securely joined by welding, which is the standard construction method.

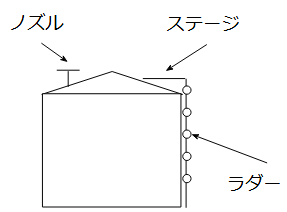

Names of Accessories

In addition to the plates that form the tank body, tanks are equipped with various accessories.

The three most common accessories are:

Accessories

Nozzles are indispensable components of a tank.

They are required for introducing or discharging solids, liquids, and gases.

Strictly speaking, “nozzle neck” might be the correct term, but in practice, these terms are often used interchangeably.

Stages and ladders are installed on tanks above a certain size.

As tanks grow larger, direct access to the top becomes impossible. Stages and ladders provide safe access.

Stages may also be called platforms, and ladders may be referred to as steps, depending on the context and tank size.

For smaller tanks, vertical access equipment such as ladders or monkey ladders is used.

For larger tanks, spiral staircases are common.

Stairs are safer but increase construction complexity and cost.

The terminology can become ambiguous—whether “stage” refers to a platform or steps.

I personally use ladder = monkey ladder and stairs = steps to distinguish them.

Whether this ambiguity is a strength or weakness of chemical plants is open to interpretation.

Nozzles are welded directly to the tank body.

Ladders and stages are typically mounted using brackets welded to the tank, then bolted on.

This makes transportation and installation easier.

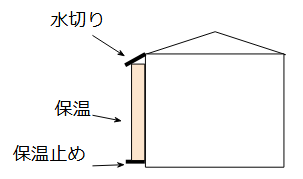

Names Related to Insulation

A tank is essentially complete with its body and accessories.

Insulation, however, is optional and depends on operating conditions.

Insulation is used to maintain a constant internal temperature—similar to insulation used in building walls.

Whether insulation is required must be decided before tank fabrication.

If insulation is applied, the structure generally includes the following components:

Insulation

Insulation material is wrapped around the outer surface of the tank shell.

To secure it, metal plates are installed at the top and bottom.

I refer to these as:

- Drip edge (top): prevents rainwater from entering the insulation

- Insulation retainer (bottom): prevents insulation from slipping downward

The insulation itself is fixed by welding nuts to the shell and fastening with bolts.

Drip edges and insulation retainers are usually welded directly to the tank.

These are simple, analog components used to physically hold materials in place.

Once the tank is fabricated, modification becomes nearly impossible if hazardous materials are present inside.

Using welding torches on an operating tank poses serious fire and explosion risks.

That is why insulation requirements must be firmly decided at the design stage.

Conclusion

Chemical plant tank structures can be understood by dividing them into three categories:

- Main body: roof plate, shell plate, bottom plate

- Accessories: nozzles, stages, ladders

- Insulation: drip edges, insulation retainers

Understanding tanks this way allows beginners to learn efficiently.

Some components have multiple names, but knowing the commonly used field terminology is essential for design, maintenance, and operation.

Feel free to post any questions or concerns about chemical plant design, maintenance, or operation in the comments section.

All comments will be carefully reviewed and answered sincerely.

Comments