In chemical plants, piping systems are connected mainly by two methods: flanged connections and welded connections.

Understanding the characteristics of both methods—and knowing when to use each—is an essential skill for engineers.

For example, in plants where flanged connections are the standard, completely rejecting welded connections as “unacceptable” can unnecessarily reduce design flexibility. The opposite is also true.

Good engineers understand the differences and make informed choices.

This article explains the practical differences between flanged and welded pipe connections in an easy-to-understand way for beginners.

Understanding RF and FF Flanges: A Beginner’s Guide for Piping Design and Maintenance

Flanged vs Welded Pipe Connections: Key Differences for Beginner Plant Engineers

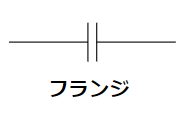

Flanged Connections

Let’s look at the advantages of flanged connections compared with welded connections.

Advantages of Flanged Connections

- Easy installation and removal

- No hot work on site

- Can be used for inspection and cleaning

Although the number of advantages seems limited, the ability to install and remove piping easily is overwhelmingly valuable in real plant operations.

Easy Installation and Removal

Piping inevitably degrades over time, and replacement work is unavoidable.

In plants that undergo frequent modifications or expansions, intentionally inserting flanged sections can significantly reduce future modification costs. This approach is especially effective in batch-type chemical plants.

Flanged connections are also useful in confined spaces where on-site welding is difficult or impossible.

No Hot Work on Site

Because flanged connections do not require welding, no flames are used on site.

In chemical plants handling flammable or explosive process fluids, welding near operating equipment requires extreme caution and is sometimes outright prohibited. Even when allowed, extensive preparation—such as fireproof sheets and portable gas detectors—is necessary.

From a maintenance and operation standpoint, flanged connections are often more practical and time-efficient.

Useful for Inspection and Cleaning

Flanged connections can serve as temporary inspection or cleaning access points.

They are particularly favored in slurry systems with a high risk of blockage, as well as in batch plants where frequent cleaning and product changeovers are required.

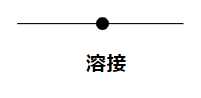

Welded Connections

Here, “welded connections” refers to direct pipe-to-pipe welding, mainly butt welding, without using flanges.

(Socket welding for high-pressure lines exists, but it is rarely used in typical batch chemical plants.)

Advantages of Welded Connections

- Fewer welding steps overall

- Lower leakage risk

- No concern about gasket or bolt deterioration

- Lighter weight

- Lower total cost in many cases

Fewer Welding Steps

At first glance, welding may seem more labor-intensive—but in practice, it is often the opposite.

When connecting pipes with flanges:

- Each flange must be welded to the pipe (inside and outside)

- Two flanges are required per connection

As a rough estimate, flanged connections may require up to four times the welding effort compared to direct welded joints.

While exceptions exist (e.g., stub ends), this comparison holds true in general practice.

Lower Leakage Risk

Welded connections eliminate gasket-related leaks.

For process fluids that must not leak to the atmosphere or come into contact with air or moisture, welded connections are often the preferred solution.

However, for highly corrosive fluids, lined piping (such as glass-lined systems) may be more appropriate.

Welded steel piping is also commonly used for utility lines requiring long-term reliability.

No Gasket or Bolt Deterioration

Welded connections avoid issues related to gasket aging and bolt corrosion.

Gaskets require periodic replacement, and bolts can corrode to the point where removal becomes extremely difficult. Welded connections eliminate these maintenance concerns.

Lightweight

Welded connections are lighter because they do not include heavy flanges.

In plants with frequent piping changeovers, reducing piping weight can significantly improve work efficiency. In some cases, minimizing flanges has been a key breakthrough in improving maintenance operations.

Lower Cost

In many cases, welded connections result in lower overall cost.

Reduced welding work, fewer components (flanges, gaskets, bolts), and simpler assembly can outweigh the higher skill level required for welding. While site conditions vary, this cost advantage is common.

Conclusion

This article compared flanged and welded pipe connections for chemical plants.

In my own plant, flanged connections are used most frequently due to modification flexibility and hot-work restrictions. Still, welded connections have clear advantages and are selected when appropriate.

There is no universally “better” option.

Understanding the characteristics of each method is the key to making sound engineering decisions.

Comments