In chemical plants, backflow in piping systems can cause serious damage to products, equipment, and even plant safety.

Manual valves depend on operator action and are prone to human error, while automated valves require power, control systems, and higher costs.

This is where check valves play an important role. They prevent backflow automatically—without operation or external power.

However, check valves are not always reliable by default. If selected or installed incorrectly, they may provide a false sense of security.

In this article, we explain the basic types of check valves used in chemical plants, their strengths and weaknesses, and practical selection tips—especially for beginners.

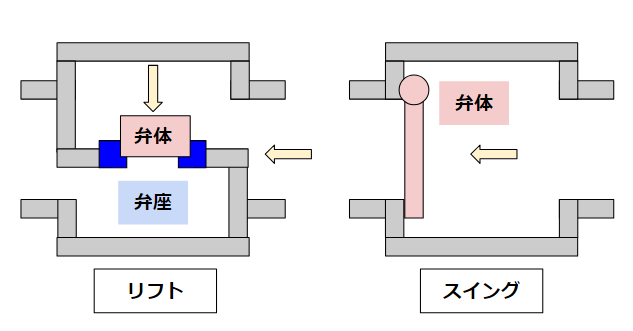

Basic Types of Check Valves: Lift vs. Swing

The most fundamental check valve designs are lift type and swing type.

Their key characteristics are summarized below.

| Item | Lift Type | Swing Type |

|---|---|---|

| Installation direction | Limited (horizontal only) | Flexible (horizontal & vertical) |

| Pipe size | Small diameters only | Large diameters possible |

| Pressure loss | Higher | Lower |

| Sealing performance | Good | Moderate |

| Service life | Relatively long | Moderate |

The difference lies in how the disc moves.

- Lift type valves open and close by vertical movement of the disc.

- Swing type valves operate by rotating the disc around a hinge.

Because the disc motion of lift valves is perpendicular to flow direction, installation orientation is restricted.

Lift Type Check Valves

Lift check valves work properly when installed in horizontal pipelines.

If installed in vertical piping, gravity interferes with disc movement, and the valve may not function correctly.

Lift valves are typically limited to small diameters.

However, their structure is similar to globe valves, resulting in good sealing performance and relatively long service life due to the absence of hinge wear.

Swing Type Check Valves

Swing check valves have fewer installation restrictions and can be used in both horizontal and vertical lines.

They are suitable for large-diameter piping and generally have lower pressure loss than lift types.

Although sealing performance is slightly inferior, their versatility makes them the most common choice in many plant systems.

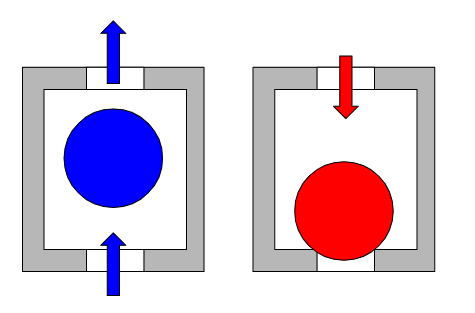

Ball Check Valves

Ball check valves operate on a concept similar to lift types.

A ball inside the valve body rises with forward flow and seats to block reverse flow.

Unlike lift valves, the disc movement direction is the same as the flow direction, and gravity is used for operation.

As a result, ball check valves are suitable only for vertical piping.

Their major advantage in chemical plants is that they can be lined, making them useful in highly corrosive services.

However, flow direction is fixed, and liquid holdup can become a concern.

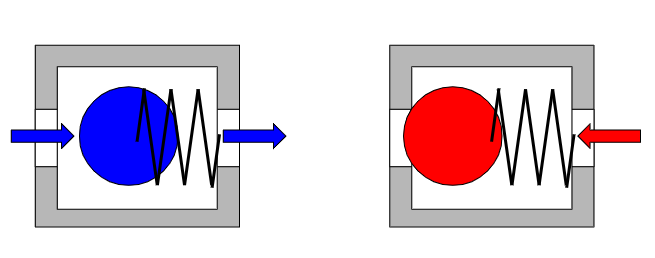

Spring Check Valves

Spring-loaded check valves are designed to overcome gravity-related limitations.

By using a spring, the valve can operate regardless of installation orientation.

At first glance, this seems ideal.

However, in chemical plants, springs are a weak point.

In corrosive process environments, springs often fail much earlier than expected.

When a spring breaks, the valve may lose its backflow prevention function, and broken fragments can contaminate products or damage equipment.

Considering the risk versus benefit, spring check valves should be used with extreme caution in chemical processes.

The simplicity of lift and swing mechanisms exists for a reason.

Conclusion

Check valves are essential components for preventing backflow in chemical plants, but they must be selected carefully based on service conditions and piping layout.

- Lift type: Small diameter lines where sealing performance is critical

- Swing type: Large diameter lines with flexible installation requirements

- Ball type: Corrosion-resistant, lined systems in vertical piping

- Spring type: Convenient, but high risk in corrosive environments

Even beginners can design safer piping systems by understanding valve characteristics and installation constraints—rather than relying on check valves blindly.

Comments