Valve leakage is a critical issue that directly impacts the safe operation of industrial plants. One key component in preventing leaks is the gland packing. However, without understanding its types, proper selection, and maintenance, gland packing itself can become a source of trouble. In this article, we explain, from a mechanical engineering perspective, why gland packing may leak and how to manage it effectively.

What is Gland Packing?

Gland packing serves as a seal between the valve stem and the valve body. While sometimes blamed for leaks, gland packing is reliable when used appropriately. Leaks occur when the packing is not suited to the operating conditions.

In most valves, the strength hierarchy is:

- Valve body: metal

- Stem seal: gland packing

- Pipe connection: gasket

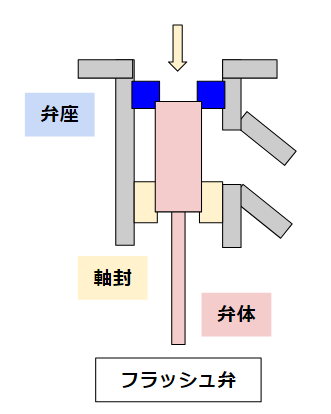

Thus, gland packing is often the first component to experience wear or leakage due to its role as a moving seal, compared to static gaskets. For highly reliable operations, bellows seals can be considered instead of gland packing, especially in batch plants or in valves like flush valves.

Common Weak Points by Valve Type

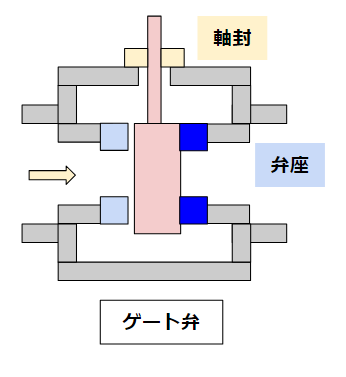

Gate Valves:

Composed of metal body, body gasket, and gland packing. Gland packing is the first point of potential leakage.

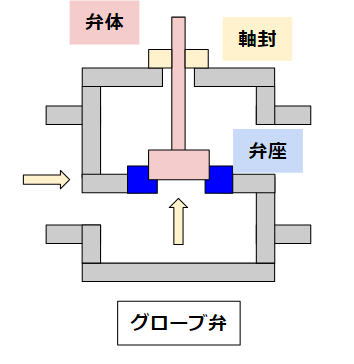

Globe Valves:

Similar to gate valves, the gland packing remains the weakest link.

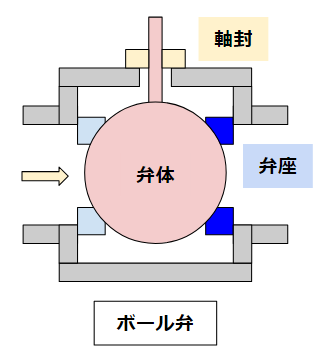

Ball Valves:

The main difference is the effect of trapped liquid expansion. Liquid trapped between the ball and the valve body can harden around the gland packing, potentially disrupting the strength hierarchy and causing leaks. Frequent operation reduces this risk.

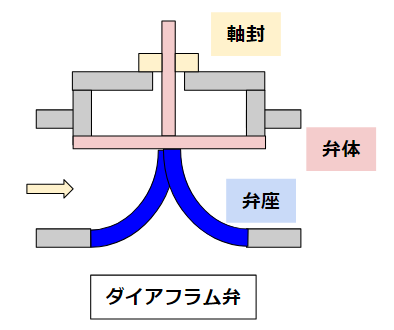

Diaphragm Valves:

The diaphragm is typically the weakest part. If it fails, leakage can occur at the gland packing or body gasket depending on the failure pattern.

Flush Valves:

Also have gland packing as the weakest component. Because they are downward-facing and often used in high-frequency operations, bellows seals are preferred for increased reliability.

Maintenance and Selection Tips

- Regular inspection and adjustment of gland packing are essential.

- Choose gland packing appropriate for the valve type and operational conditions.

- Consider bellows seals for high-reliability requirements, as they avoid frictional wear.

- Understand the strength hierarchy: Gasket > Bellows > Gland Packing.

Conclusion:

Gland packing is a crucial component in preventing valve leakage. By understanding its types, proper selection, and maintenance methods, plants can achieve safe and efficient operation while minimizing unexpected leaks. Proper management prevents downtime and ensures reliability in chemical plant operations.

Comments