When selecting a shaft sealing system for pumps, many engineers struggle with one fundamental question:

“Which sealing method is actually the safest choice?”

In chemical plants, this decision is rarely simple. Hazardous fluids, strict leakage regulations, and limited cooling options often complicate seal selection.

In such situations, double mechanical seals are frequently chosen as a reliable and conservative solution.

This article explains why double mechanical seals are often the safest option in real chemical plant operations, focusing on practical, on-site considerations rather than theory.

Why Mechanical Seals Leak in Pumps — and How to Fix It

What Is a Gland Packing (Gland Seal)? A Clear Guide to Its Purpose, Mechanism, and Use Cases

Top 3 Mechanical Seal Flushing Plans Explained (API 682 Standards)

Essential Guide to Mechanical Seal Support Systems in Chemical Plants

Seal Basics for Chemical Plants: How to Prevent Leakage Through Proper Design and Selection

What Is a Labyrinth Seal in Chemical Plants?

Why Do Large-Diameter Seals Leak?

1. Stronger Protection Against Process Fluid Leakage

The most obvious advantage of a double mechanical seal is its two-layer sealing structure.

With a single mechanical seal, once the seal face fails, leakage is immediately released to the atmosphere.

In contrast, a double mechanical seal adds an additional barrier, significantly reducing the probability that hazardous fluids escape outside the pump.

For chemical plants handling toxic, flammable, or environmentally regulated fluids, minimizing external leakage is a top priority.

This alone often justifies the selection of a double seal.

2. More Flexible Cooling and Barrier Fluid Options

Cooling and flushing are common challenges in seal design.

Water is often used as a seal flush, but many chemical processes cannot tolerate water contamination.

Single mechanical seals with self-flushing designs may avoid external cooling, but they introduce risks such as clogging—especially in slurry or solid-containing services.

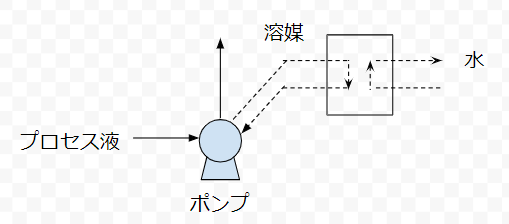

Double mechanical seals offer greater flexibility:

- Direct circulation of compatible solvents

- Indirect cooling using barrier fluids

- Pressurized barrier systems for higher safety

From a risk-management perspective, indirect cooling with a clean barrier fluid is often the safest and most controllable solution.

3. Maintenance Costs Do Not Increase as Much as Expected

It is true that double mechanical seals are more expensive than single seals.

However, the difference in total lifecycle cost is often smaller than expected.

When considering:

- Production losses due to leaks

- Emergency shutdowns

- Cleanup and recovery work

- Safety incidents

A double mechanical seal may actually reduce total operating costs.

In practice, many plants use single seals for most pumps while reserving double seals for a limited number of critical or high-risk services.

This targeted approach balances cost and reliability effectively.

4. Seal-less Pumps Are Not Trouble-Free Either

Seal-less pumps are often viewed as the ultimate solution to leakage problems. While they eliminate external seals, they introduce other challenges:

- Poor performance with slurry or solid-containing fluids

- Limited material and model options

- Difficult failure detection (problems occur internally and invisibly)

Although double mechanical seals still rely on barrier fluids, leakage detection is generally easier and more predictable compared to seal-less designs.

From a practical standpoint, double mechanical seals remain a robust and understandable option for many applications.

✅ Conclusion

If you are unsure which shaft sealing system to choose, starting with a double mechanical seal is often the safest decision.

Key advantages include:

- Minimized leakage risk

- Greater flexibility in cooling and flushing methods

- Competitive total lifecycle cost

- Stable performance under complex operating conditions

Double mechanical seals are not universal solutions—but when safety, reliability, and risk reduction matter most, they are frequently the best choice in chemical plants.

About the Author – NEONEEET

A user‑side chemical plant engineer with 20+ years of end‑to‑end experience across design → production → maintenance → corporate planning. Sharing practical, experience‑based knowledge from real batch‑plant operations. → View full profile

Comments