Expansion joints are small but crucial components in piping systems. Used correctly, they absorb thermal movement, reduce stress, and isolate vibration—letting you design longer, safer, and more reliable runs. Used incorrectly or omitted, they can cause leaks, pipe failures, or equipment damage. This article summarizes common types of expansion joints and practical guidance on where and how to use them in chemical plants.

Types of expansion joints (and when to choose each)

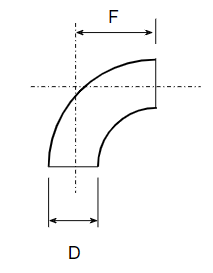

Elbows

The simplest “expansion” element: an elbow (bend) changes pipe geometry so thermal growth is absorbed by curvature instead of transmitted down the line. Elbows are ubiquitous and provide passive expansion absorption in many plant layouts. Use them where small angular movements and simple routing suffice.

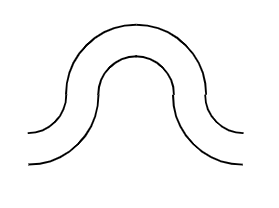

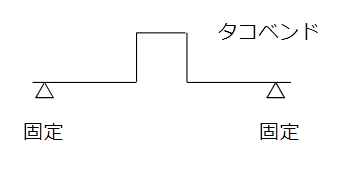

Taco-bend (expansion bend)

A taco-bend (often seen on steam mains) uses multiple bends in a short length to create a long effective expansion path. It’s common on long, high-temperature runs (e.g., steam at >150°C). For long external rack piping, place taco-bends every so often to limit thermal stress.

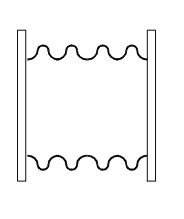

Bellows (metal or lined)

Bellows (corrugated joints) offer axial, angular, and lateral flexibility in a compact form. Metal bellows handle larger movements; PTFE-lined or PTFE-covered bellows are used where corrosion resistance or lining compatibility is required. Choose metal bellows for high expansion tolerance; use PTFE-lined bellows for lined pipes and corrosive services.

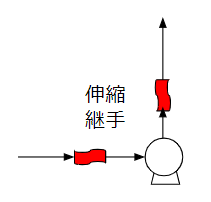

Flexible hoses / flexible tubes

Flexible hoses are like long bellows and are the go-to for vibration isolation and where significant movement or frequent disconnection is expected. They’re common at vibrating machinery connections (centrifuges, vibrating dryers) and at load-cell interfaces to prevent pipe loads transferring to instruments. Design carefully — long flexible elements take more strain and can fail more easily.

Typical application cases — practical tips

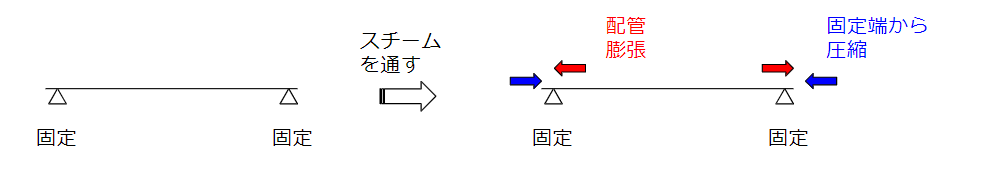

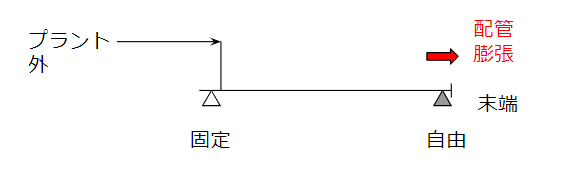

High-temperature, long-distance piping (steam mains)

Thermal expansion is large (ΔT often >100°C). Use taco-bends or dedicated expansion loops. Where space is limited, allow one side to slide (one free end) and fix the other. Always check thermal growth calculations and add supports accordingly.

Connections to high-vibration equipment

For centrifuges, vibrating dryers, and other oscillating machines prefer flexible hoses over simple bellows — they tolerate dynamic loads better. Ensure anchors and supports isolate the vibration and do not transmit loads to fragile equipment.

Lined (glass/PTFE) piping connections

Lined pipes and lined equipment (glass-lined reactors, PTFE-lined pumps) are sensitive to pipe movement. Use bellows with compatible linings (PTFE-covered bellows) and provide robust supports so the bellows — not the lining — bear the movement. Avoid transmitting bending moments to lined nozzles.

Load cell (weighing) installations

To prevent pipe weight and pump thrust from loading a load cell, use flexible connections (short flexible hoses) so the load cell only senses the tank weight. Check that piping supports and anchors prevent axial or lateral loads reaching the cell.

Design & installation practicalities

- Calculate thermal growth (α·ΔT·L) and choose joints rated for required movement.

- Combine methods when needed (elbows + bellows + sliding supports) rather than relying on a single “magic” joint.

- Support placement: add guides and anchors so expansion is absorbed where intended; uncontrolled movement causes fatigue.

- Material compatibility: match bellows material or lining to the process fluid and temperature.

- Fatigue & cycle life: bellows have limited cycles — verify life expectancy under expected thermal/vibration cycles.

- Prevent buckling: long flexible sections need lateral restraint or guiding to avoid instability.

- Vendor consultation: always validate complex cases with the manufacturer and include safety factors.

Comments