In many chemical plants, vibrating sieves are commonly used to control the particle size of powder products. They might look like simple, quiet machines sitting in a corner—but if you ignore their mechanical design or safety requirements, they can become a source of serious accidents.

This article explains how vibrating sieves work and highlights key design and safety considerations that every plant engineer should keep in mind.

1. The Role of Vibrating Sieves

Vibrating sieves (or vibrating screens) are designed to separate powders based on particle size. Although manufacturers may differ, the overall structure is generally similar.

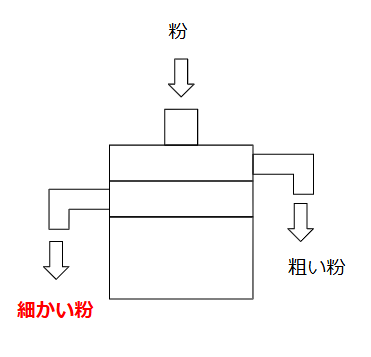

The sieve’s primary function is to classify particles—for example, separating fine powders as product and returning coarse powders for reprocessing. This simple mechanism ensures consistent product quality in powder production.

2. Structure and Working Principle

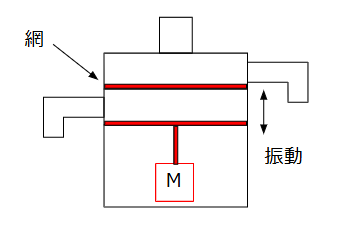

Screening with Mesh Layers

A vibrating sieve uses mesh screens to physically separate particles—similar to filtration but based on size rather than solubility. Powders fall by gravity onto the upper mesh layer.

Fine particles pass through the mesh openings to the lower chamber, while coarse particles remain above. The vibration, generated by a motor, ensures continuous movement and automatic discharge of both fractions.

Some systems include rubber balls (tapping balls) between the mesh layers. These lightly strike the mesh during operation, helping to prevent clogging and providing a limited crushing effect. Whether to use them depends on the powder’s properties—sometimes it’s safer to exclude them if unnecessary.

Vibration Mechanism

A motor located beneath the sieve provides the vibration energy. The lower sieve chamber transmits this energy to the upper chamber, often through springs that synchronize motion.

As the entire assembly moves, powder flows outward and downward toward discharge outlets. Unlike many process devices in chemical plants, vibrating sieves are visually dynamic—when in operation, you can clearly see them moving.

3. Safety Precautions

Keep Personnel Away

Since the entire sieve structure vibrates, contact poses a physical hazard. Always use warning signs, ropes, or barriers to restrict access.

Even though the machine produces noise and vibration that discourage close contact, relying on that alone is unsafe. Clear physical separation between workers and the equipment is the best practice.

When collecting product powder into drums, avoid placing containers directly beneath the vibrating sieve. Ideally, locate them on a lower floor or design the layout to separate human access from the operating equipment.

Dust Explosion Risk

One of the most serious hazards when using vibrating sieves is dust explosion.

When the discharge port and receiving drum are connected by a sleeve, continuous operation can create electrostatic buildup—especially if the sieve body is isolated from ground (floating potential) and the sleeve is made of nonconductive material.

To prevent ignition, evaluate the minimum ignition energy (MIE) of the powder and ensure proper bonding and grounding. This eliminates charge accumulation and minimizes explosion risk.

Conclusion:

Vibrating sieves are simple, reliable machines, but their simplicity can lead to complacency.

Understanding their mechanical design and applying proper safety measures—especially grounding, physical barriers, and explosion prevention—are essential for safe operation in chemical plants.

By respecting these fundamentals, you ensure consistent product quality and plant safety.

Comments