Even after completing the design of a tank or piping system, it cannot be used immediately.

Before operation, engineers must confirm that the equipment has been fabricated correctly and meets the required strength and tightness.

This confirmation is done through pressure testing — a crucial step to ensure safety and reliability.

In this article, we’ll introduce the three most common pressure tests used in industrial plants:

- Hydrostatic Test: Confirms strength under pressure

- Leak (Air Tightness) Test: Detects leaks in welds or joints

- Water-Filling Test: Verifies installation stability for large outdoor tanks

Each test serves a different purpose and requires specific safety considerations.

Let’s go through how each is performed, what it proves, and when to use which.

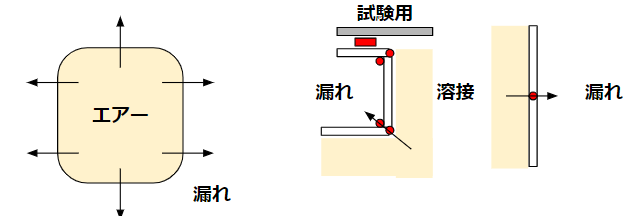

1. Leak (Air Tightness) Test

The air tightness test checks whether an equipment is properly sealed.

Compressed air (or sometimes nitrogen) is introduced into the vessel or piping to verify there are no leaks.

Common inspection methods include:

- Applying soapy water on welds and flanges to check for bubbling

- Monitoring pressure drop over time

- Listening for leak sounds

Because gases are less dense than liquids, they leak more easily—making this method ideal for detecting small imperfections.

However, it also means higher risk. If a rupture occurs during testing, it can cause serious injury or equipment damage.

Therefore, air tightness tests are performed at a slightly lower pressure than hydrostatic tests (e.g., 1.1 × design pressure).

This balance ensures effective leak detection without excessive stress on the vessel.

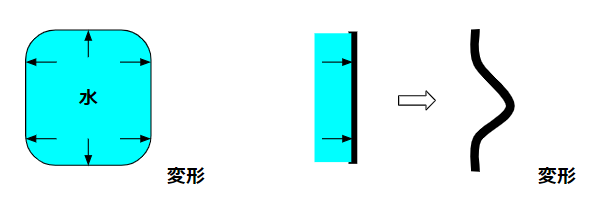

2. Hydrostatic Test

The hydrostatic test checks the mechanical strength of tanks or piping.

Water is filled into the equipment and pressurized using a pump.

Key points:

- Pressure is raised to 1.25–1.5 times the design pressure

- The system is held under pressure for a set time

- Engineers visually inspect for deformation or leakage

Because water is nearly incompressible, it’s much safer than using air or gas at high pressure.

This test confirms that the equipment can withstand operational stress without deformation or rupture.

Although the vessel’s strength should be ensured by design and calculation, fabrication errors—such as incorrect thickness or poor welding—can lead to problems.

Hence, the hydrostatic test is the final assurance before commissioning.

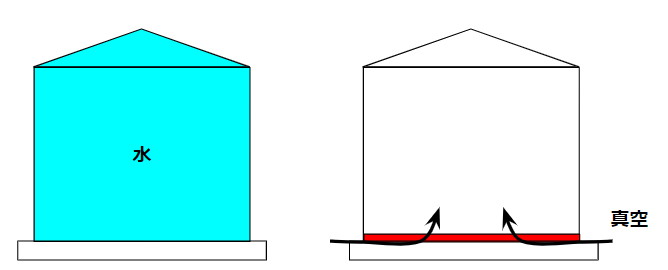

3. Water-Filling Test (for Outdoor Tanks)

The water-filling test is a simpler version of the hydrostatic test, often used for large storage tanks that operate at low pressure.

It verifies that the tank is structurally sound and properly seated after installation.

The test involves filling the tank completely with water and checking for:

- Deformation or settlement

- Bottom plate leaks using a vacuum box test

- Side weld inspections (usually done with dye penetrant checks)

Because outdoor tanks usually store liquids lighter than water, testing with water provides a safety margin.

For heavier liquids (like sulfuric acid), engineers must evaluate the test pressure and material strength more carefully.

Note: Air tightness tests are not suitable for such low-pressure tanks, as external temperature changes can affect pressure readings and invalidate results.

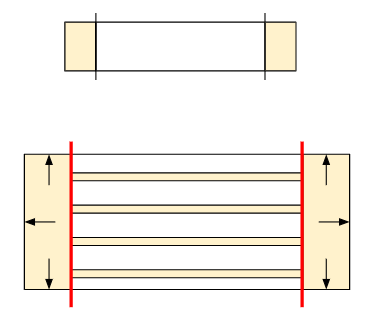

4. Combined Testing (Example: Heat Exchanger)

In multi-component equipment such as shell-and-tube heat exchangers, both the shell side and tube side require separate tests.

- Shell-side test:

Performed with the shell cover removed.

Air or nitrogen is applied to check leaks at tube-to-tube sheet welds using soapy water. - Tube-side test:

Conducted after the shell cover is installed.

Pressure is applied inside the tubes to confirm tightness between tube sheets and gaskets.

In some cases, temporary gaskets are used during testing to prevent damaging the actual process seals.

This combination ensures both internal and external joints maintain integrity under different pressure conditions.

Conclusion

Pressure testing is the final step before plant equipment enters operation.

It ensures that design strength and sealing performance are both satisfied.

Here’s a quick summary:

- Hydrostatic Test → Strength verification

- Leak (Air Tightness) Test → Seal and leakage check

- Water-Filling Test → Installation and stability confirmation

By applying the correct test for each purpose, engineers secure the safety, reliability, and long-term performance of tanks and piping systems.

Comments