Cyclone separators are a familiar tool in powder-handling processes, used to separate particulate matter from gas streams. They’re often seen as a simple solution for capturing escaped powder for reuse or disposal. But when it comes to reintegrating collected powder into upstream processes, things can get complicated.

This article breaks down the two common cyclone configurations—standalone (split) and direct-return (inline)—and the often-overlooked design challenges they present. If you’re considering a cyclone for your powder process line, this guide will help you avoid hidden risks such as backflow, contamination, and poor separation performance.

🔍 Main Content

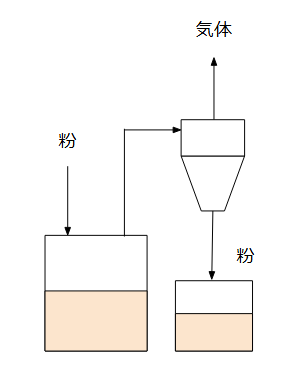

📌 Cyclone (Split-Type) Configuration

A classic setup features a cyclone downstream from a powder container (e.g., hopper or tank), where entrained powder is separated and collected from the exhaust gas. A blower is often used to generate suction from the cyclone’s outlet, while a valve at the cyclone bottom periodically discharges collected powder.

However, this setup comes with critical risks:

- No valve = backflow. Gas may reverse into the cyclone if the discharge valve is missing.

- Closed valve = buildup. If the valve remains shut, powder accumulates and may escape with the gas stream.

- Reuse = contamination risk. Reintroducing collected powder upstream requires careful quality control to avoid introducing foreign material into the final product.

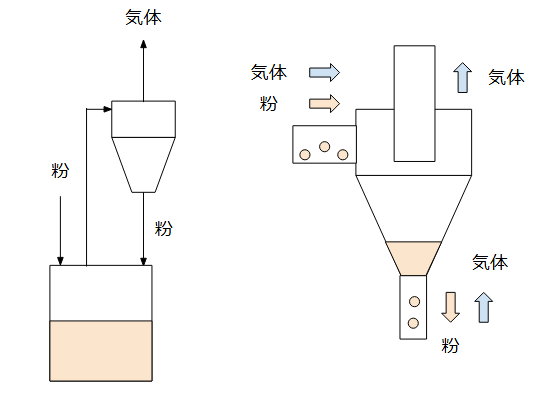

🔄 Direct-Return (Inline) Cyclone Design

In this approach, the cyclone is mounted directly atop the powder container, enabling immediate return of separated powder into the original process stream.

While this seems efficient, it introduces new challenges:

- Backflow persists. Gas reversal at the cyclone bottom remains a concern.

- Upstream suction risk. Placing the blower upstream can introduce wear particles into the product stream.

- Installation height. Cyclones must be mounted high, sometimes creating layout and safety concerns.

Even when scaled up, cyclone storage capacity brings height penalties. Initial start-up conditions, when powder is not yet accumulated, can result in backflow and separation inefficiency.

⚙️ The Automation Temptation

To mitigate these issues, automation is often considered:

- Automatic valves for timed discharge

- Powder level sensors

- Air or nitrogen purge systems to prevent reverse flow

These tools can improve reliability—but they also add complexity and cost. Valves may clog, purge lines wear down, and ironically, the automation meant to reduce contamination can itself become a source of foreign matter.

💨 Velocity and Pressure Loss

Cyclones rely on maintaining sufficient linear velocity to achieve effective separation. This leads to pressure drops, making exhaust fan selection critical.

A weak fan can’t achieve the necessary velocity; a powerful one consumes excess energy. The choice of equipment directly affects whether the cyclone will function as intended—or not at all.

Sometimes, simpler alternatives, like inertial impactors, may offer sufficient performance with fewer risks.

✅ Summary: Design with Subtraction in Mind

Cyclones are more than just powder collectors—they are critical to maintaining product quality and process efficiency. The instinct to “just add” another component often backfires in powder engineering.

Before implementation, ask:

- Where will recovered powder be returned to the process?

- How is reverse flow prevented reliably?

- Can layout constraints (height, pressure drop) be addressed?

- How is foreign material risk minimized?

Blindly stacking equipment and features leads to inefficiency. A thoughtful, subtractive design—removing unnecessary complexity—often results in better, safer, and leaner powder processes.

Comments