Steam piping is essential in many industrial processes, but improper design can cause serious problems like water hammer. This article explains the fundamentals of steam piping design and practical tips to avoid water hammer, ensuring safe and efficient plant operation.

Introducing articles from plantengineering.com.

Although steam is a relatively common substance, considerable care must be taken when designing piping.

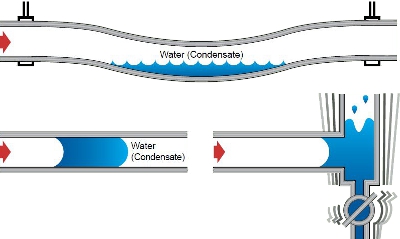

Unlike ordinary liquids and ordinary gases, it condenses from gas to liquid.

This can cause water hammer and may damage equipment such as piping.

We will explain the basics of piping design to prevent this problem.

Steam traps are installed at regular intervals

Install steam traps at regular intervals.

This is because steam condenses into water due to heat loss.

If water accumulates in steam piping, water hammer will occur.

Be especially careful with long-distance piping outside the plant.

Steam trap on rising elbow

Attach a steam trap to the piping section that rises due to the elbow.

When the flow of piping changes, the gaseous steam and liquid water tend to separate.

When water collects at the bottom of the pipe and steam rises from the elbow, water collects in the pipes at a lower location, causing water hammer.

Balance with steam supply amount

Install appropriately sized steam traps in areas that use a certain amount of steam, such as reactors.

A huge amount of condensate is generated, which is clearly different from heat loss due to outside air.

If the steam trap is small, the condensate will not be drained and water hammer will occur inside the device.

Steam trap exit is shortest

It is best to minimize the exit of the steam trap.

If liquid builds up in the pipes, the steam trap will not be able to operate properly.

As a result, water hammer is likely to occur and the steam trap will malfunction.

Conclusion

Understanding steam piping design basics and water hammer prevention is crucial for plant safety and longevity. Proper design and maintenance minimize risks and optimize steam system performance.